Ink Filling Machine - 30L Gravimetric Filler - High-Precision Packaging Equipment

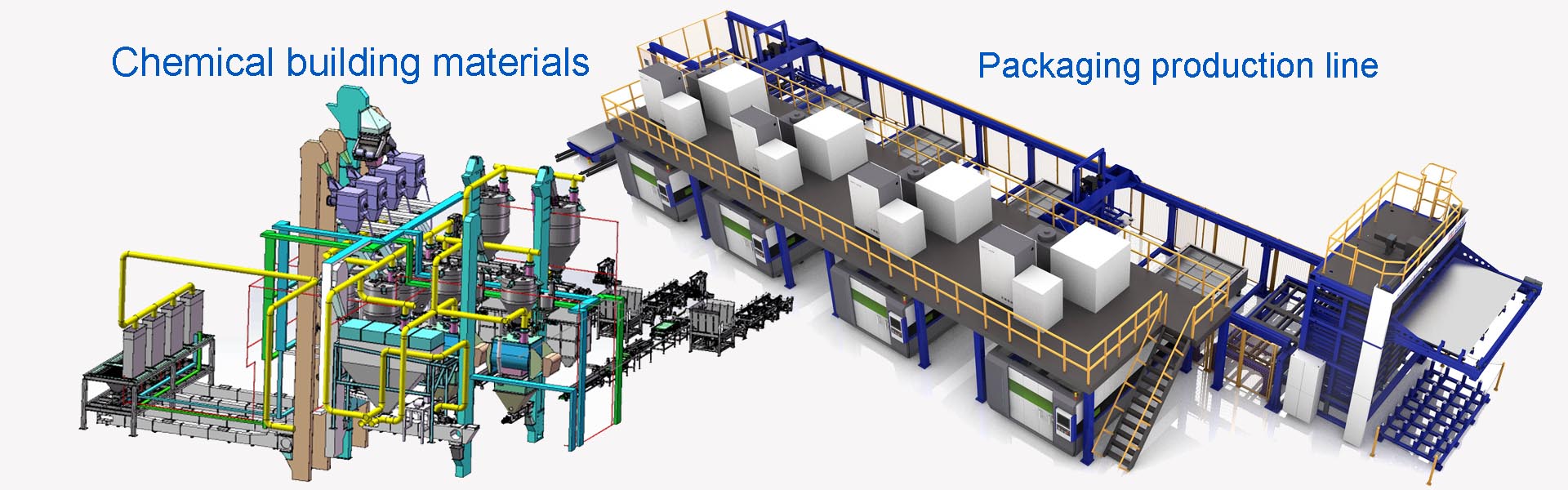

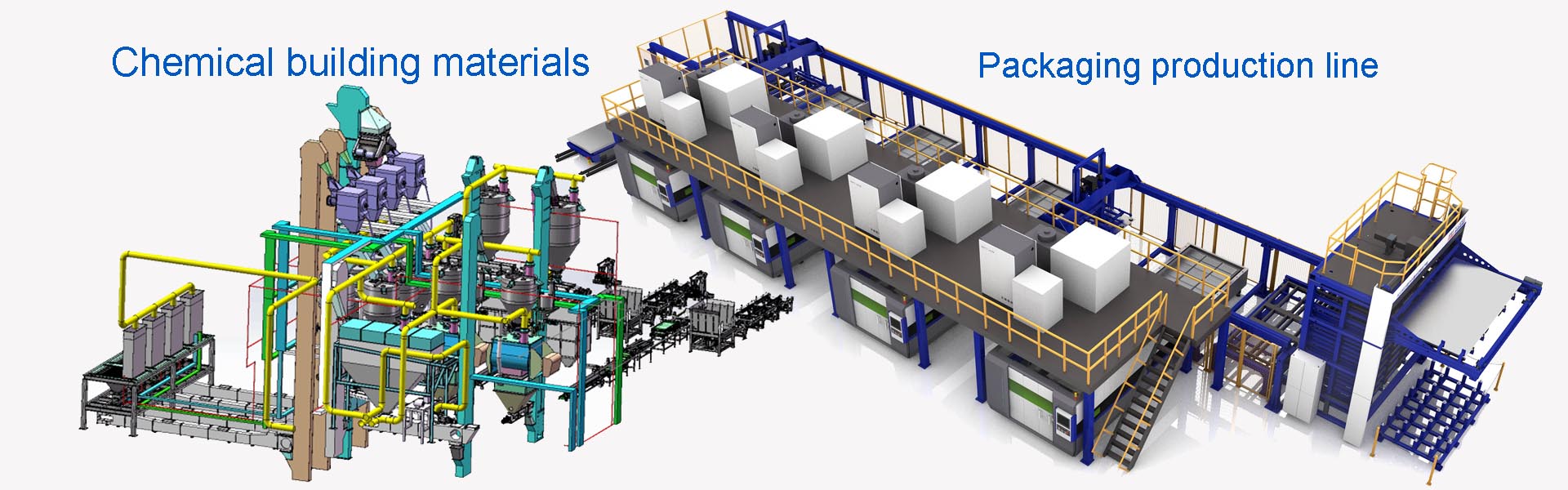

Shanghai Guangzhi Automation Equipment Co., Ltd. supplies adhesive fillers, thinner packagers, petrochemical liquid filling systems, dual-head gravimetric fillers, and compact filling machines, backed by comprehensive after-sales support. Market-driven and innovative, we deliver premium solutions tailored to client needs.

30L Ink Filling Machine | High-Precision Gravimetric Filler

Specifications:

Capacity: 10-30L

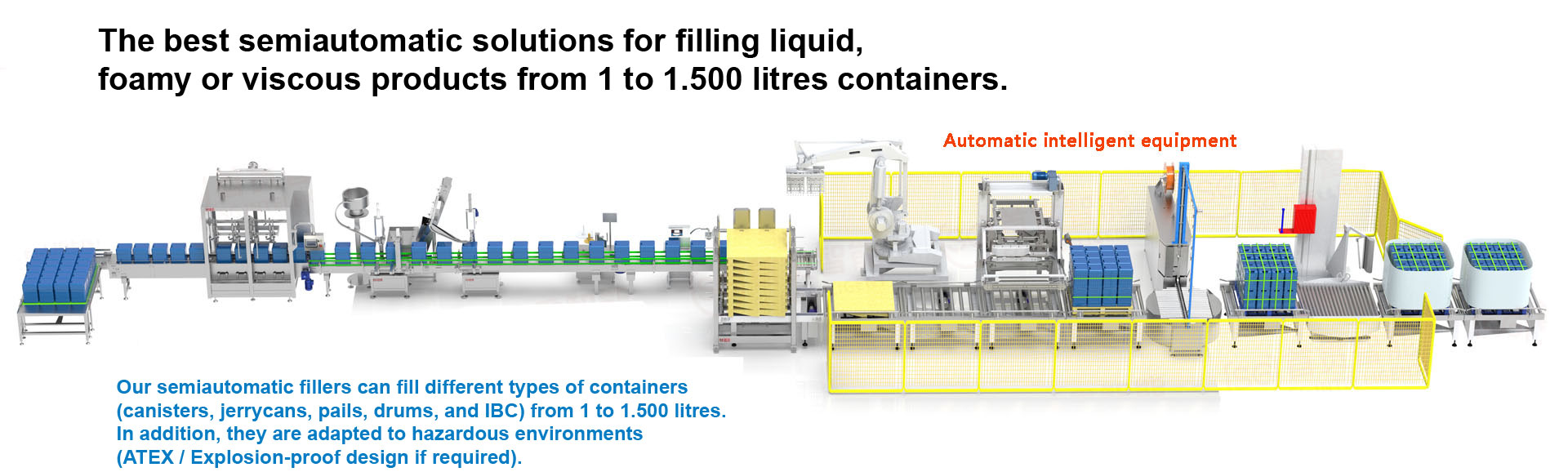

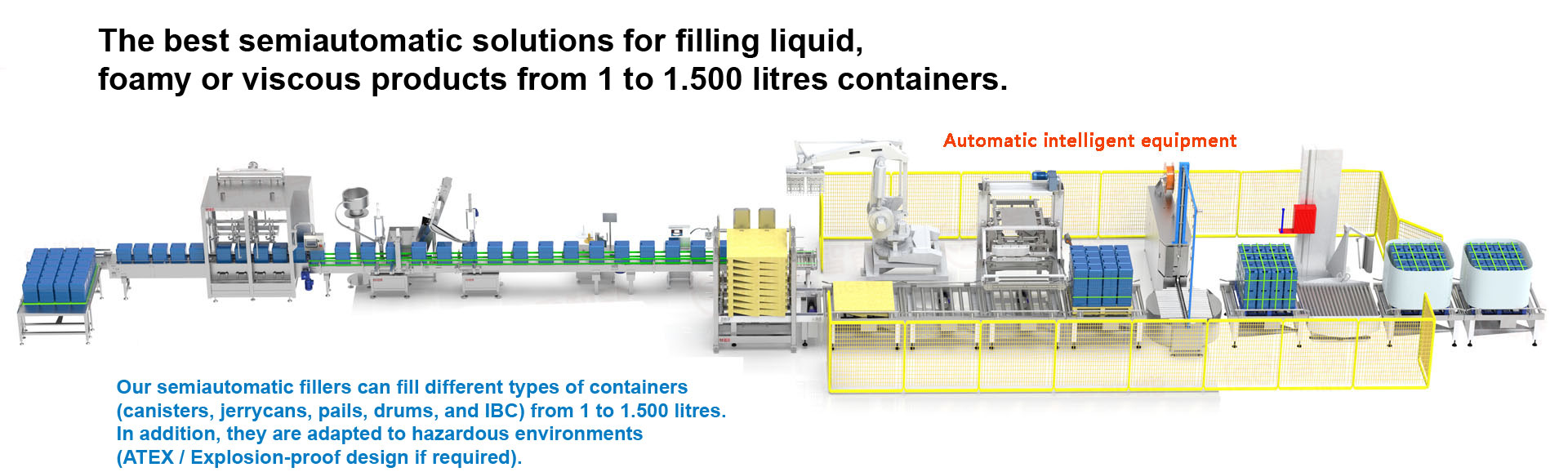

Explosion-proof: Exd II BT4

Air Pressure: 0.4–0.6MPa

Power: AC380V/50Hz, 3-phase

Speed: 8–10 drums/min (20L)

Operators: 1–2

Power Consumption: ~2kW

Noise: ≤80dB

Air Usage: ~300L/min

Key Features:

Preset Profiles – Stores 20 product recipes for quick setup.

Multi-stage Filling – 2-stage (fast/slow) or 3-stage (slow/fast/slow) modes enhance accuracy.

Leak-proof Design – High-viscosity nozzles prevent dripping; low-viscosity nozzles include drip trays.

Collision Protection – Guards against misaligned drums.

Flexible Modes – Supports top/in-can, above/below-liquid filling for diverse materials.

Operation:

A. Align drum under the nozzle.

B. Press Start:

Tare weight auto-detected.

Nozzle descends; fills via fast/slow stages.

Closes at target weight (±tolerance).

Nozzle retracts; weight verified.

C. Repeat for continuous production.

Applications:

Inks, paints, automotive coatings, adhesives, resins, solvents, lubricants, and more.

Service:

1-year warranty, lifetime maintenance.

24/7 support; on-site repairs.

Cost-price spare parts post-warranty.

Related Equipment:

16KG Emulsion Filler | Multi-purpose Packager

18KG Ceramic Ink Filler | Top-Loading Weighing System

20L Food-Grade Filler | Explosion-proof Model

25L Ceramic Ink Conveyor | ATEX-compliant

20KG Paint Capper | Linear Auto-Sealer

(Keywords: ink packaging system, precision drum filler, 30L liquid weigher)

Contact us for customized filling solutions!