LY-300 Series Automatic Filling Line

LY-300 Series Automatic Filling Line

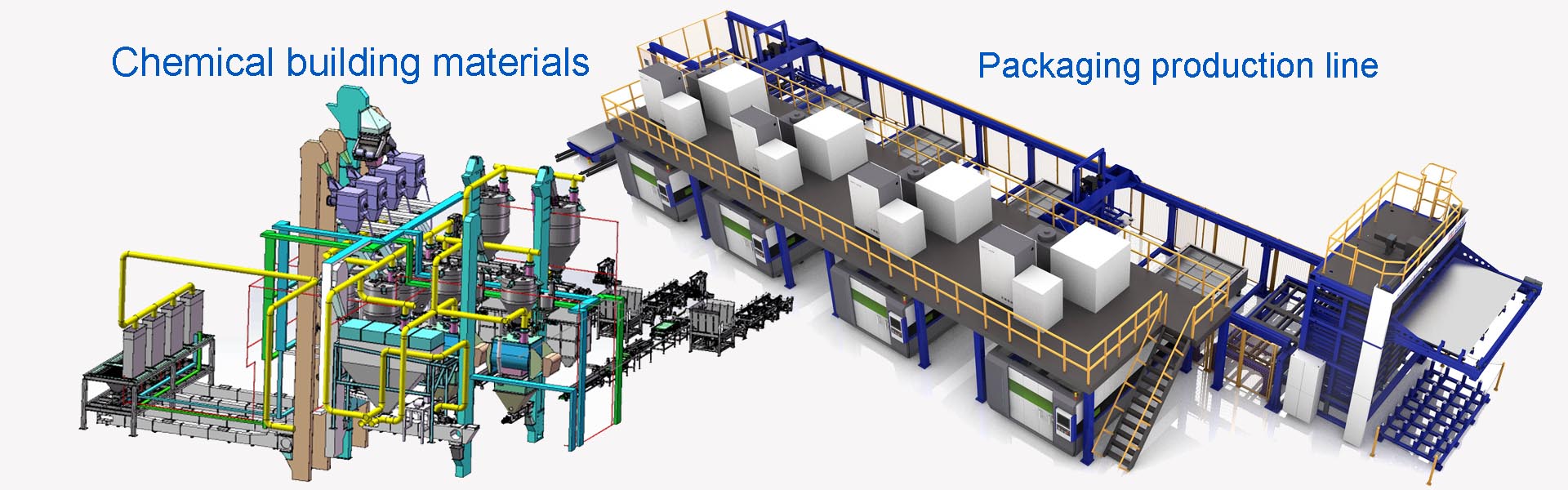

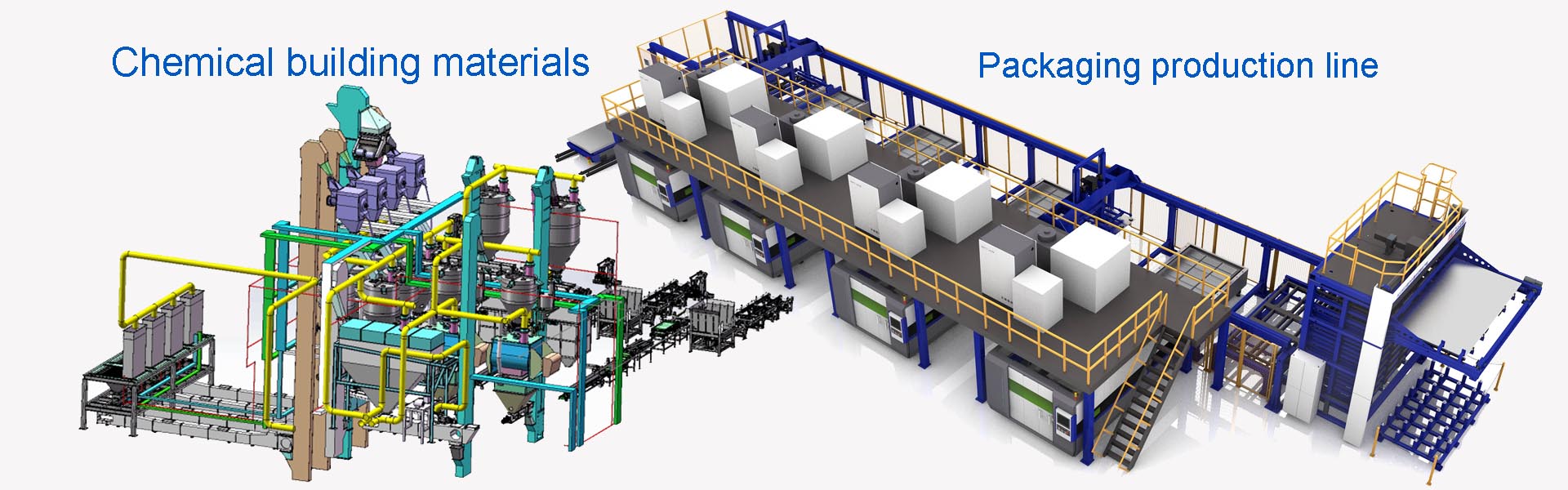

Applications:

? Flammable & Explosive Liquids: Acetone, THF, butanediol, aniline, nitrobenzene, chloromethane, MEKP, etc.

? Corrosive Liquids: Ethanolamine, PO, hydrogen peroxide, phosphoric acid, formic acid, carbonic acid, etc.

? Crystallizing/Condensing Liquids: Polyether, MDI, phenol, p-cresol, liquefied wax, etc.

? High-Viscosity Liquids: Resin, PU, adhesives, paints, asphalt, grease, etc.

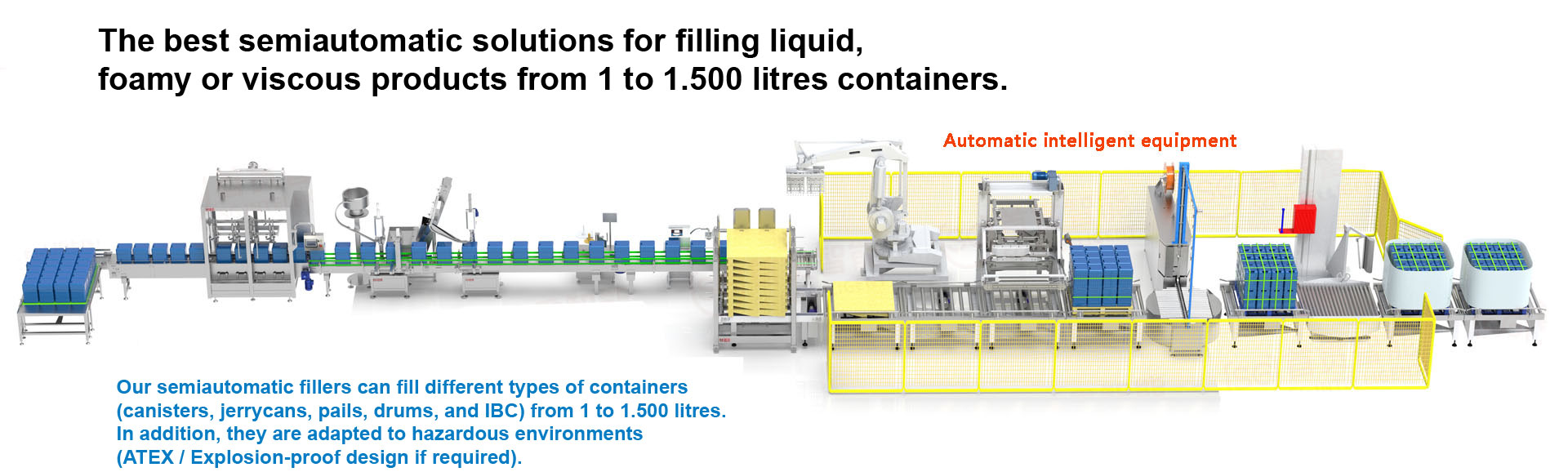

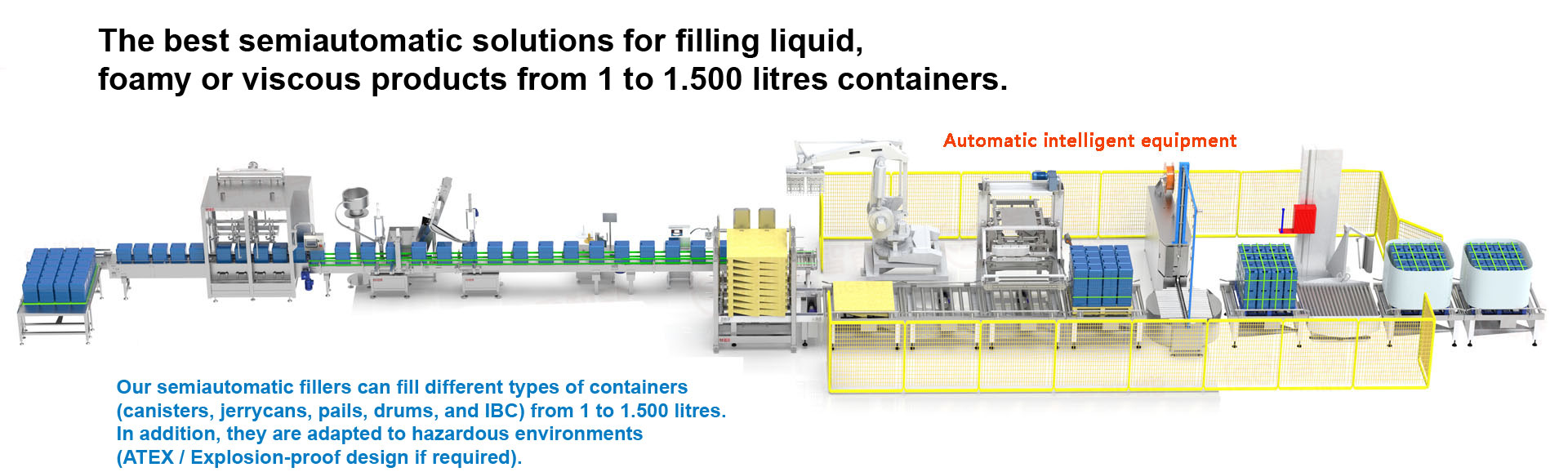

Key Features:

? 3-stage filling nozzle for precision (±0.1–0.2%)

? Auto tare detection for varying container weights

? 316/304 stainless steel & PTFE contact parts

? 10 recipe presets, fast/slow adjustable filling

? Collision prevention & auto weight correction

? Explosion-proof option (ATEX/EX II BT4/BT6)

? Auto conveyor, filling, capping & separation

? RS232/485 (DP/MODBUS optional) for data management

? Heating/N? purging (optional)

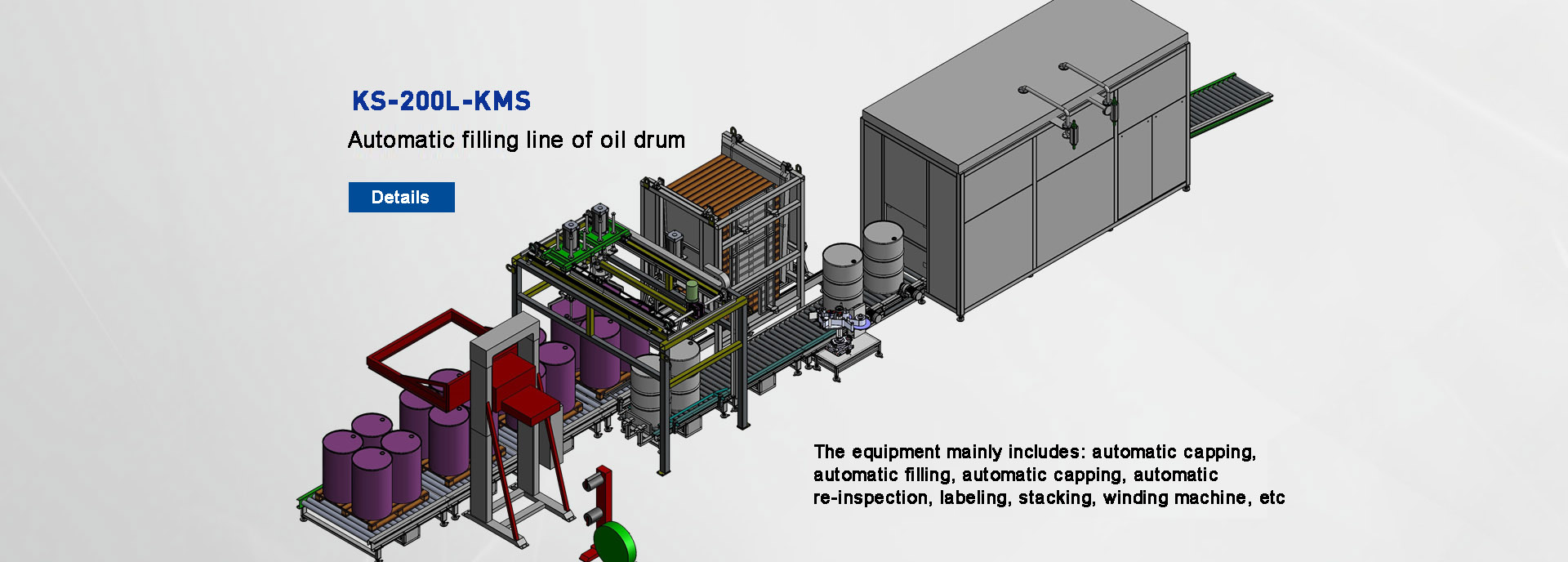

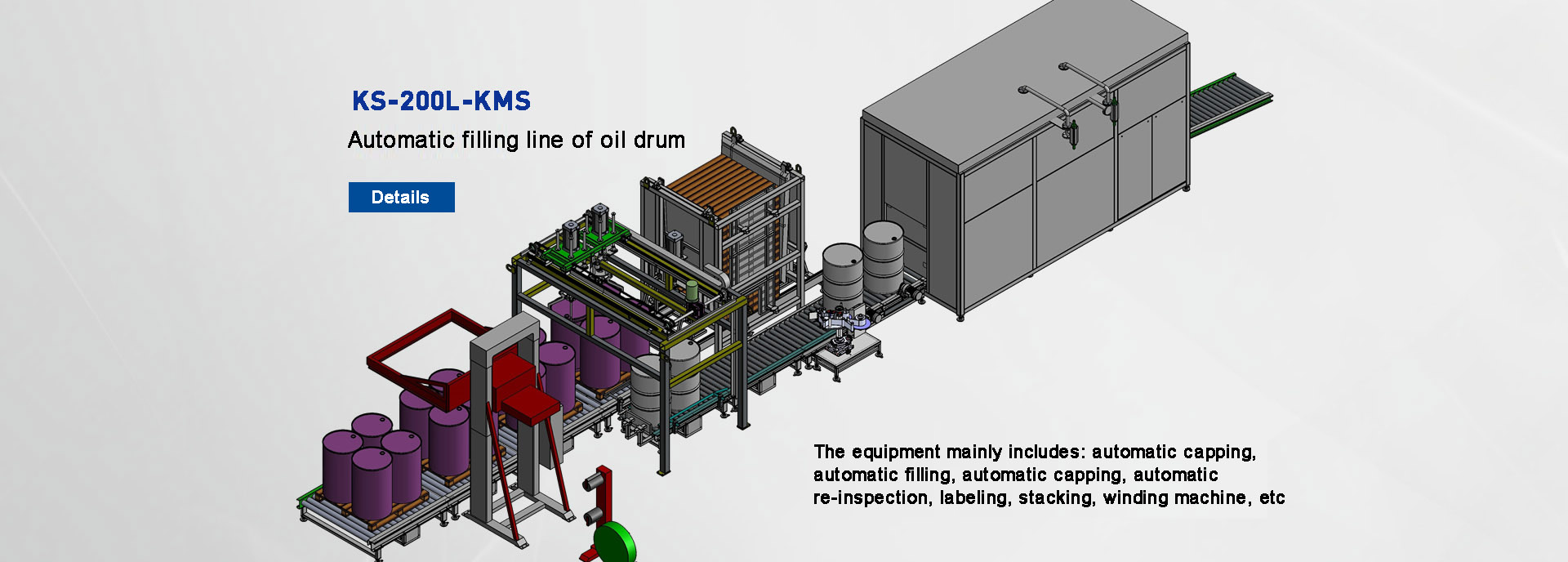

System Components:

Filling guns, explosion-proof control cabinet, Siemens PLC/weighing module, touchscreen, auto-positioning device, load cells, pneumatic actuators, stainless/carbon steel frame.

Options:

Explosion-proof kits, auto capping, N? filling, exhaust systems, labeling, palletizing.

Technical Specs:

? Capacity: 150–300kg

? Speed: 40–50 drums/hr (single-head), 90–120 drums/hr (dual-head)

? Accuracy: ±0.1–0.2%

? Power: 380V/220V, <1kW

? Air supply: 0.4–0.6MPa

Compatible with: Labelers, coders, cappers, palletizers, etc.