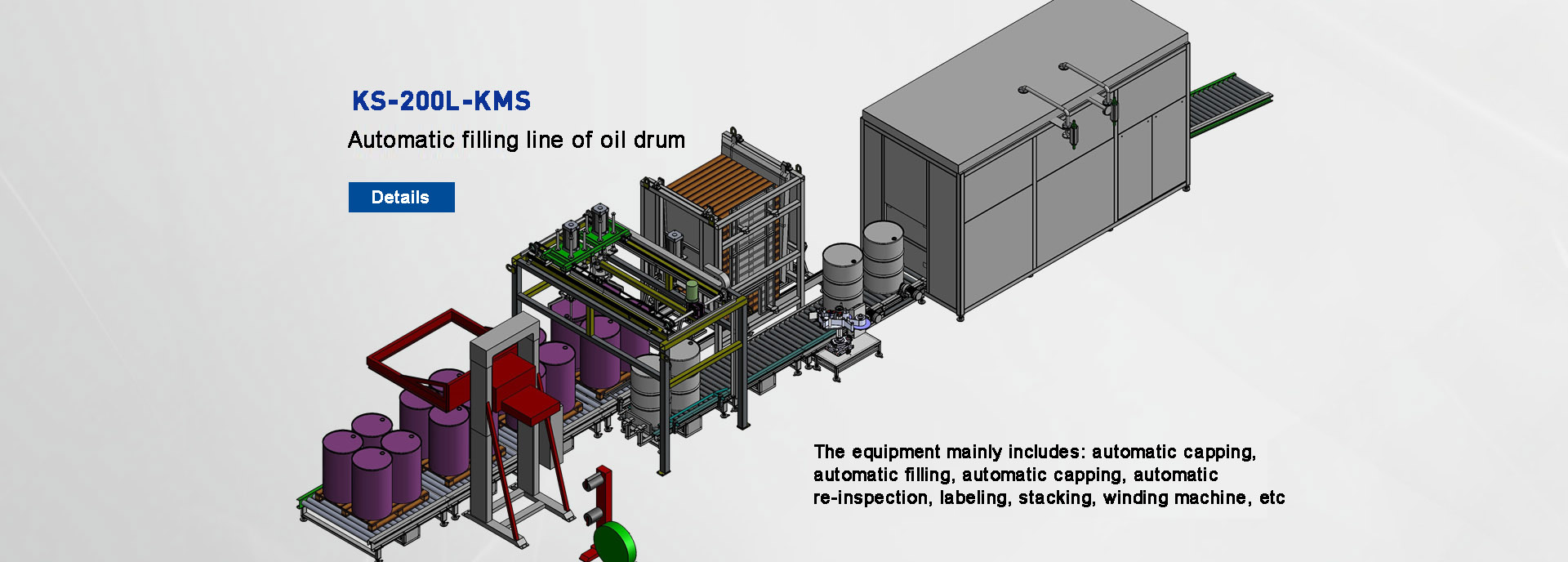

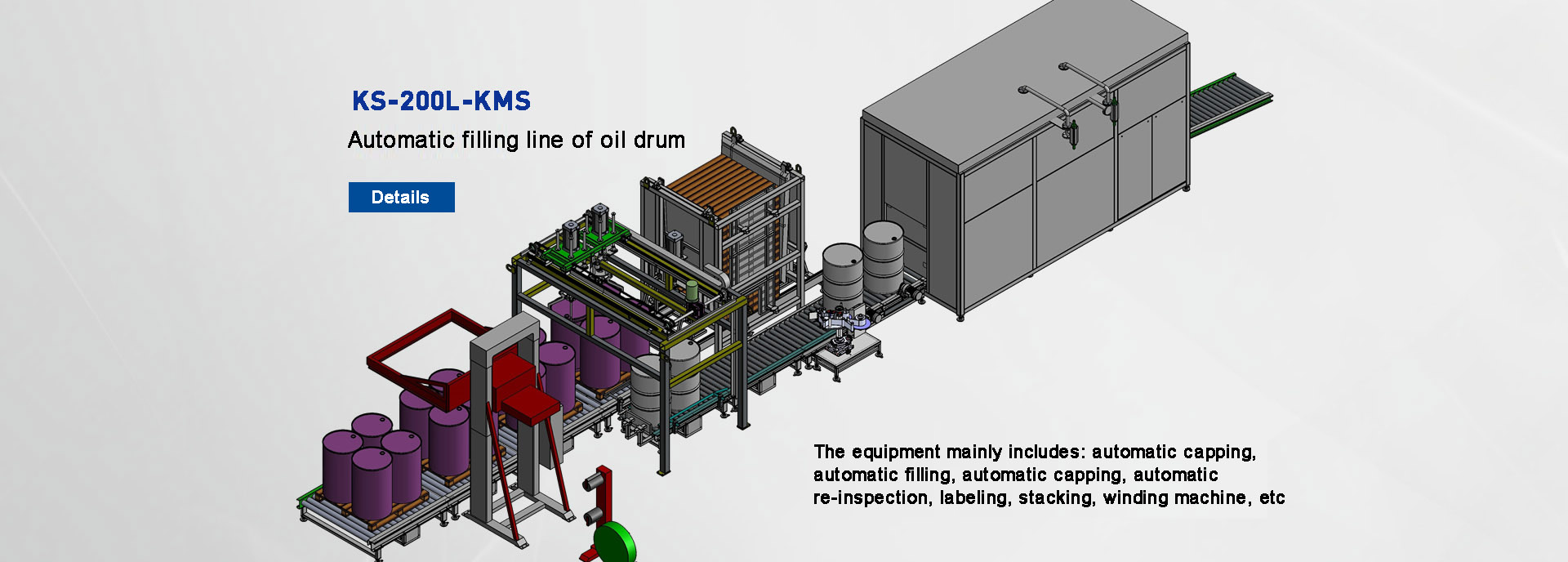

Bulk Chemical Filling System - IBC Tote & 200L Drum Filling Nozzle

Bulk Chemical Filling System | IBC Tote & 200L Drum Filling Nozzle

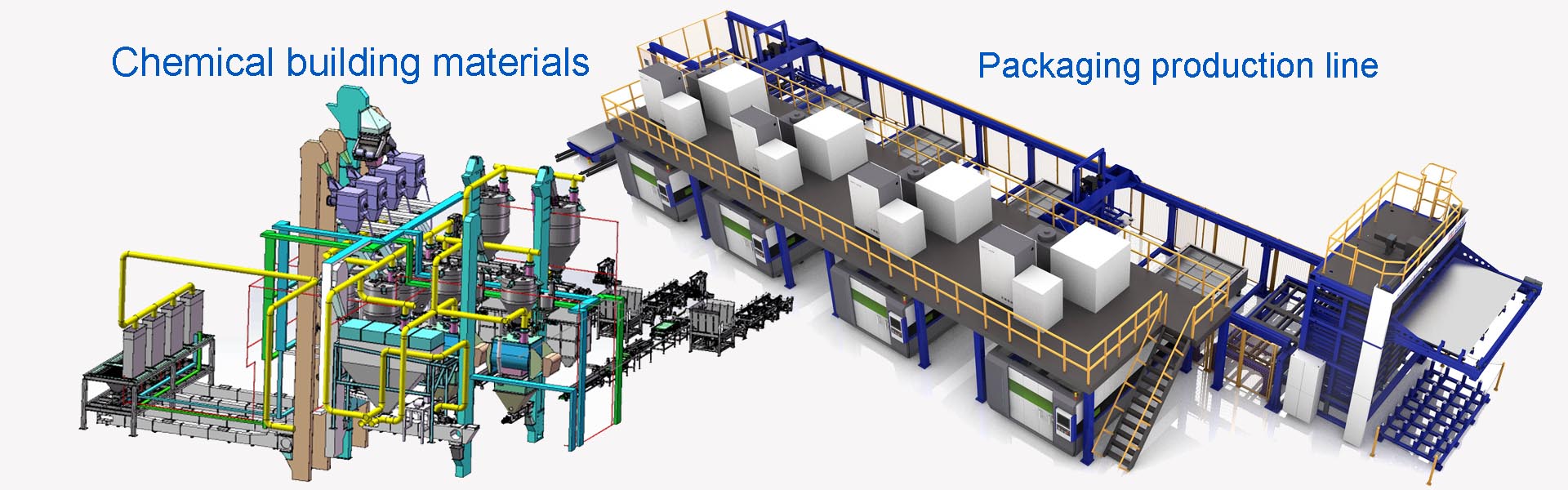

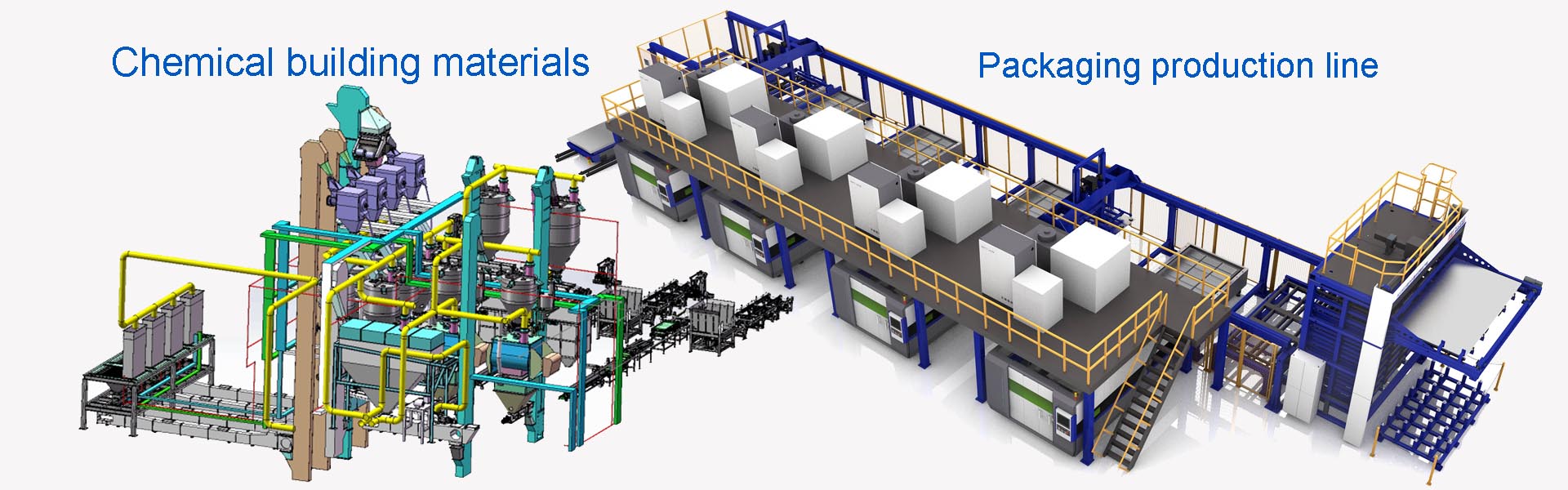

System Overview

The bulk chemical filling system is a specialized, automated solution designed for safe and precise filling of IBC totes, 200L drums, and other industrial containers. It integrates advanced nozzle technology, safety features, and robust construction to handle corrosive, hazardous, or high-viscosity chemicals efficiently.

Key Features

Precision Filling Nozzle

Accurate Control: Self-centering nozzles ensure precise alignment with container openings, reducing spills and waste.

Adjustable Flow Rates: Customizable speeds to prevent splashing or foaming during filling.

Chemical Compatibility

Material Durability: Made from stainless steel, PTFE, or chemical-resistant alloys to withstand aggressive chemicals.

Hose Options: Flexible or rigid hoses tailored for specific chemical compatibility.

Safety and Compliance

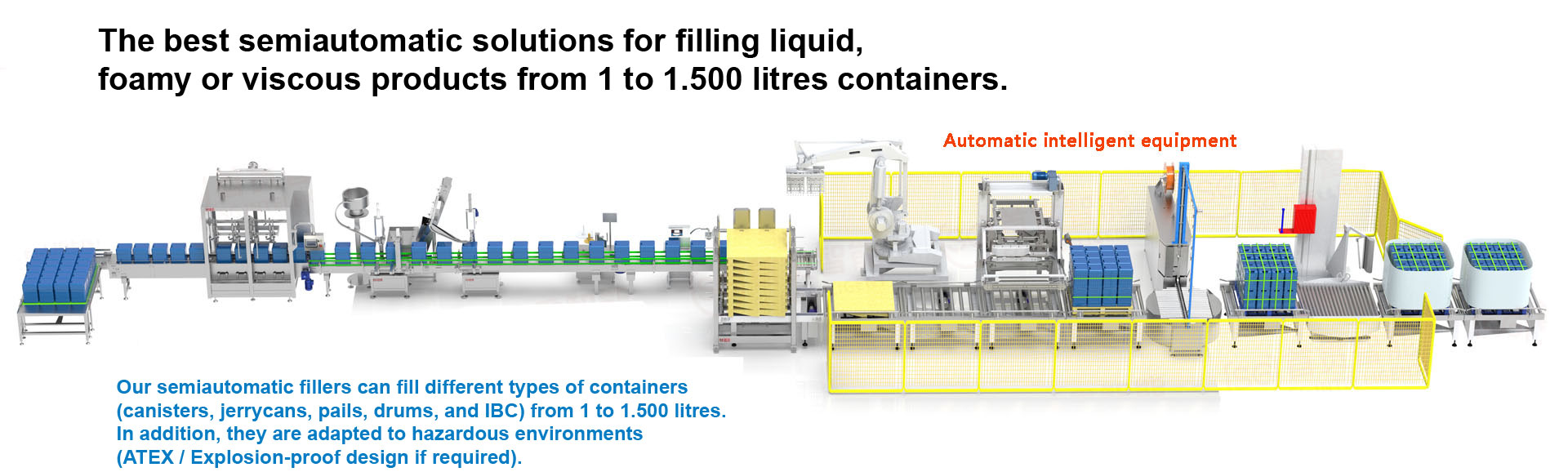

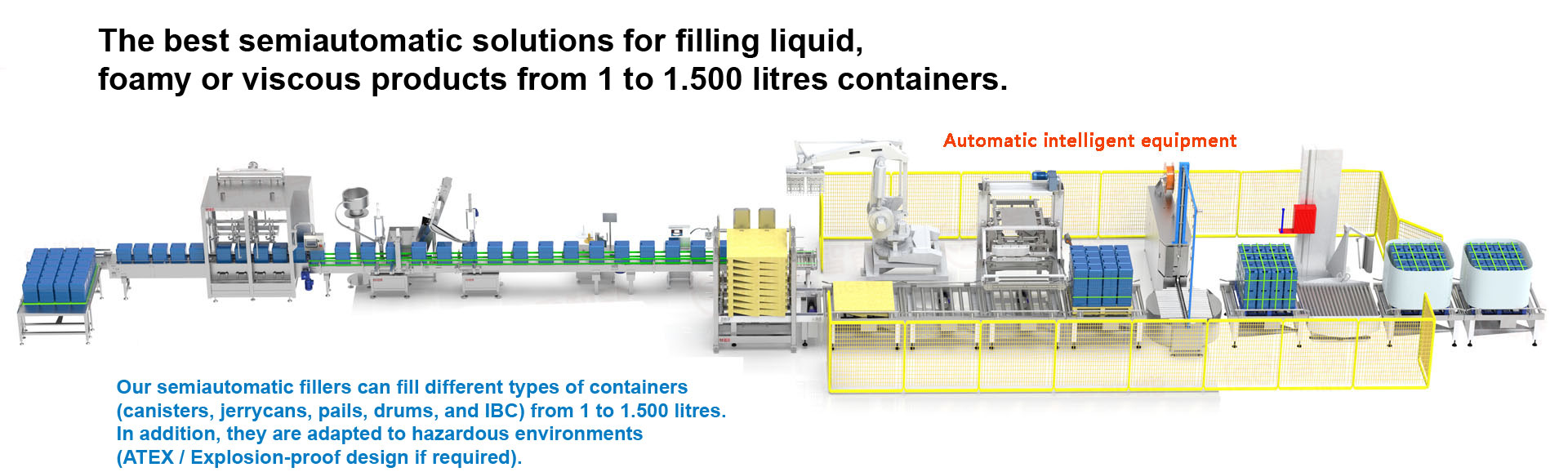

ATEX/IECEx Certification: Safe for use in hazardous environments (optional for explosive atmospheres).

Static Grounding: Ensures safe handling of flammable chemicals.

Spill Prevention: Automatic shut-off and drip-free design to minimize leaks.

Versatility

Container Adaptability: Suitable for IBC totes, 200L drums, and other standard or custom containers.

Liquid Handling: Capable of filling corrosive acids, bases, solvents, oils, and high-viscosity chemicals.

Ease of Use

Quick-Connect Design: Tool-free nozzle changes and hose connections for efficient operation.

Integrated Level Sensors: Automatically stops filling when the target volume is reached.

Durability and Low Maintenance

Corrosion-Resistant Construction: Stainless steel or coated components for longevity.

Easy Cleaning: Smooth surfaces and removable parts for quick sanitization.

Applications

Chemicals: Filling acids, bases, solvents, and hazardous liquids.

Petrochemicals: Oils, lubricants, and fuels.

Pharmaceuticals: Active ingredients, solvents, and bulk pharmaceuticals.

Food & Beverage: Edible oils, syrups, and food-grade chemicals.

Agriculture: Fertilizers, pesticides, and agrochemicals.

Benefits

Enhanced Safety: Minimizes operator exposure to hazardous chemicals.

Reduced Waste: Precision filling reduces product loss and environmental impact.

Increased Efficiency: Faster cycle times and automated processes save labor costs.

Compliance: Meets international safety standards for hazardous environments.

Customization Options

Nozzle Types: Self-centering, fixed, or manual nozzles based on application needs.

Hose Lengths: Customizable to fit your facility layout.

Special Features: Nitrogen blanketing, vacuum filling, or heating/cooling jackets.

Why Choose This System?

Proven Reliability: Trusted by industries worldwide for consistent performance.

Global Support: Available with installation, training, and after-sales service.

Cost-Effective: High-quality equipment designed for long-term use.

Get Started Today!

For a customized solution tailored to your specific needs, consult with our team. We provide consultation, installation, training, and ongoing support to ensure your success.

This description focuses on the system’s capabilities, features, and benefits without mentioning company names or contact details.

Immediate Order:

Website: http://www.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Automatic Pail Filling Equipment, Drum Filling System, Automatic Drum Filler, Automatic Palletized Drum Filler[2025-03-29]

-

200kg Liquid Ethanol Exchangeable Gun Filling Machine[2025-04-24]

-

Four-Head Corrosive Liquid Filling Line for Filling 200L Drum Detergent[2025-04-02]

-

Automatic Meter Filling Line for Filling 200L Drum Liquid/Glacial Acetic Acid/Epoxy Resin[2025-03-29]