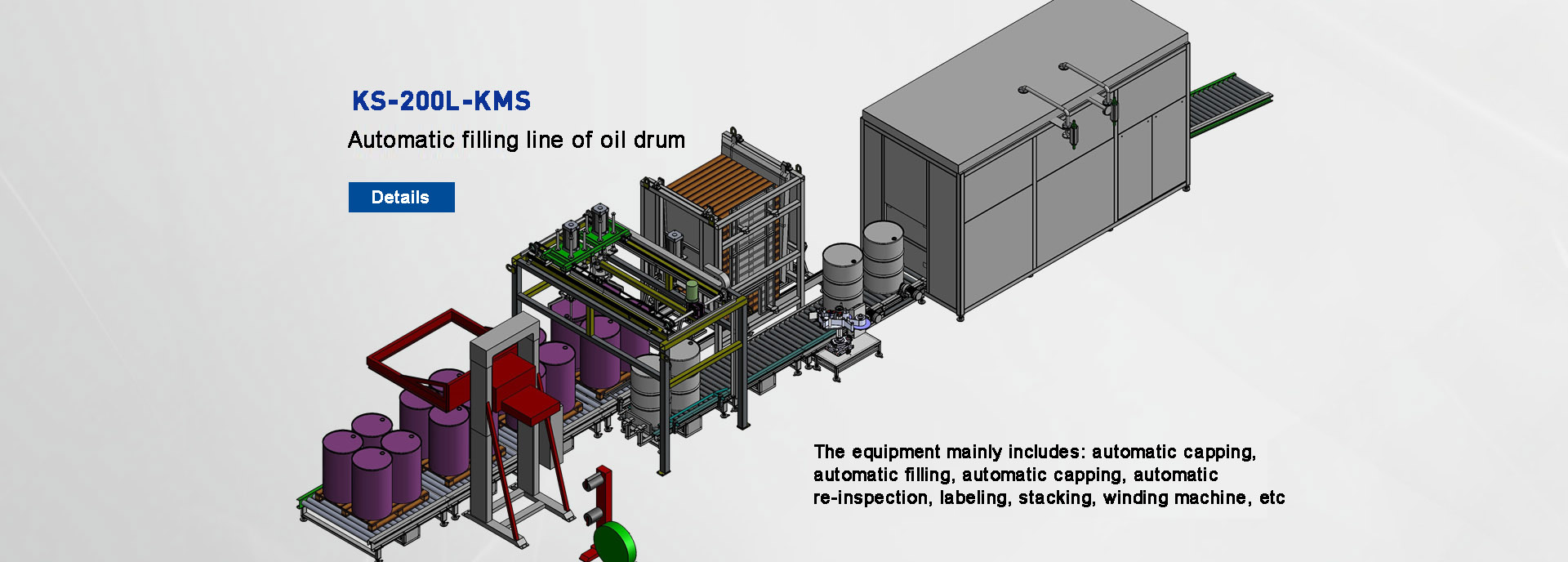

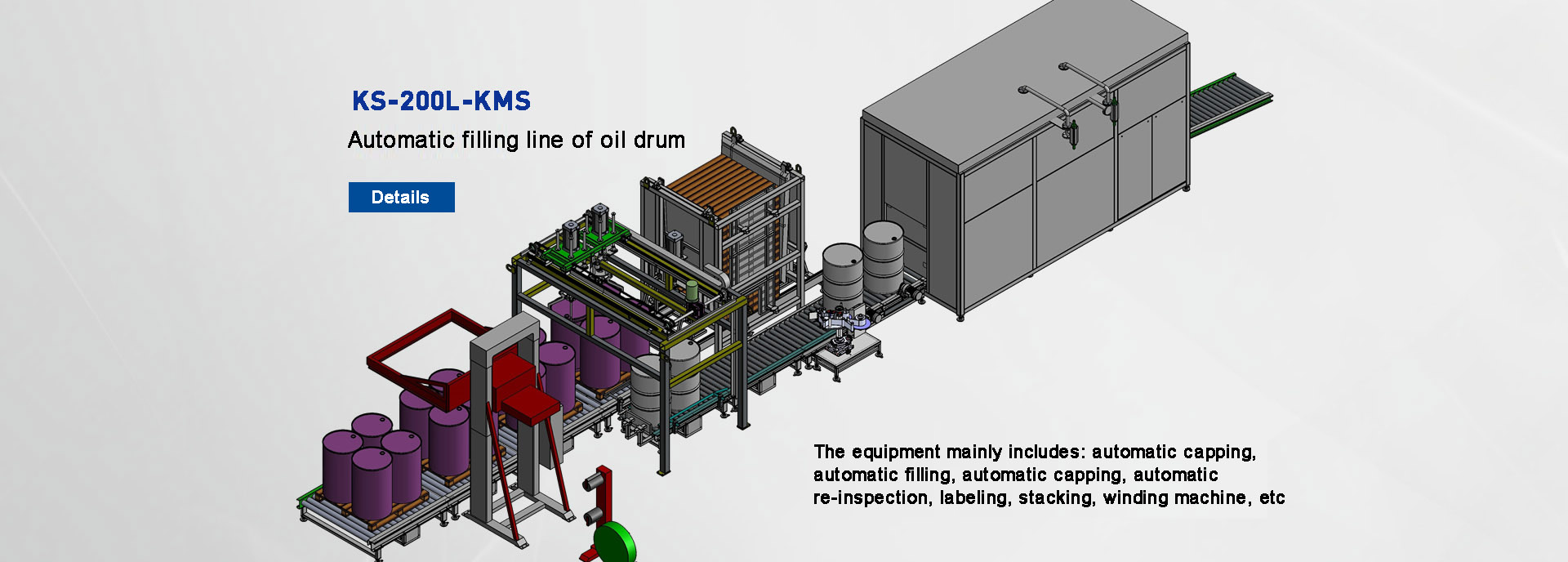

Heavy-Duty 200L Dual-Head Liquid Filling Machine

Heavy-Duty 200L Dual-Head Liquid Filling Machine

Overview

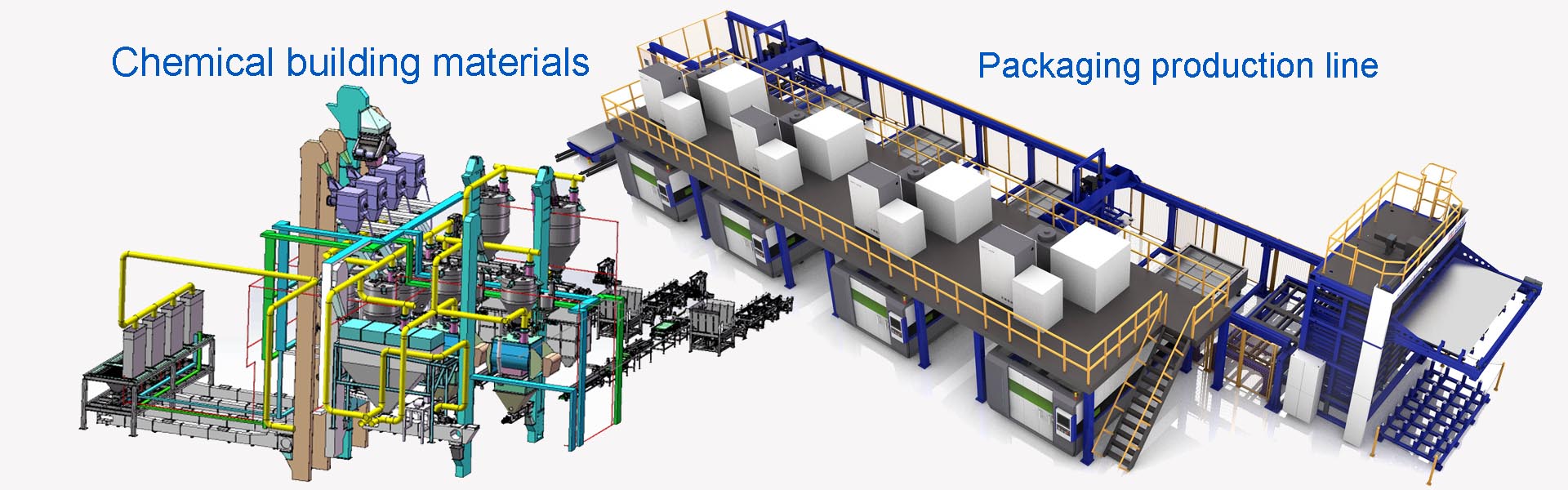

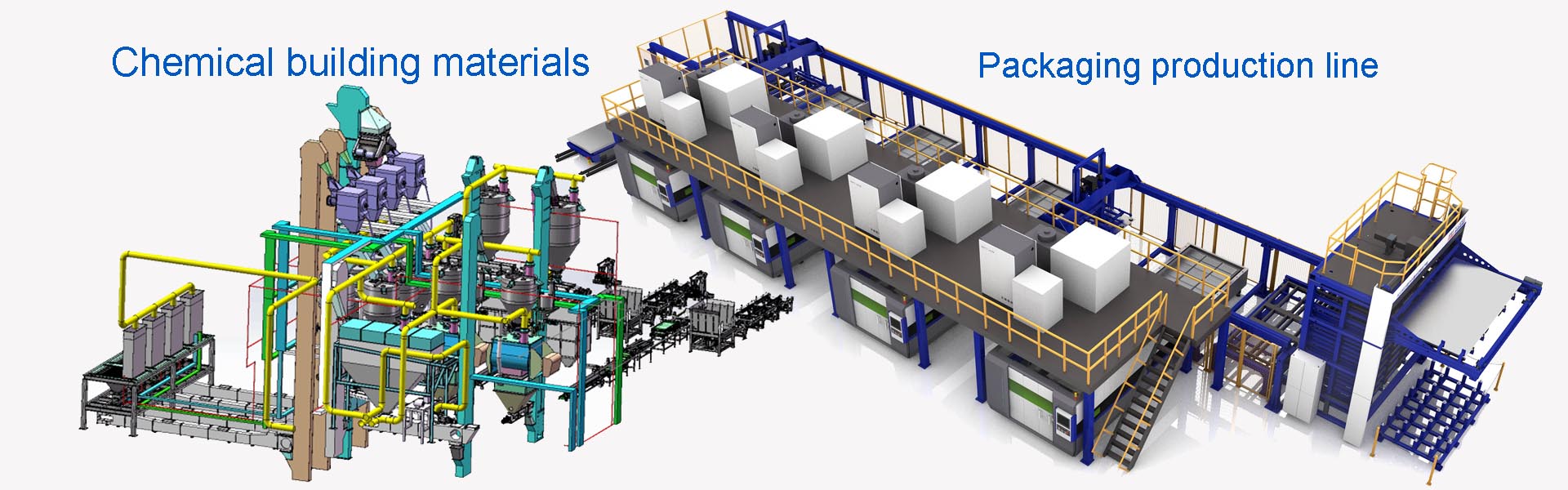

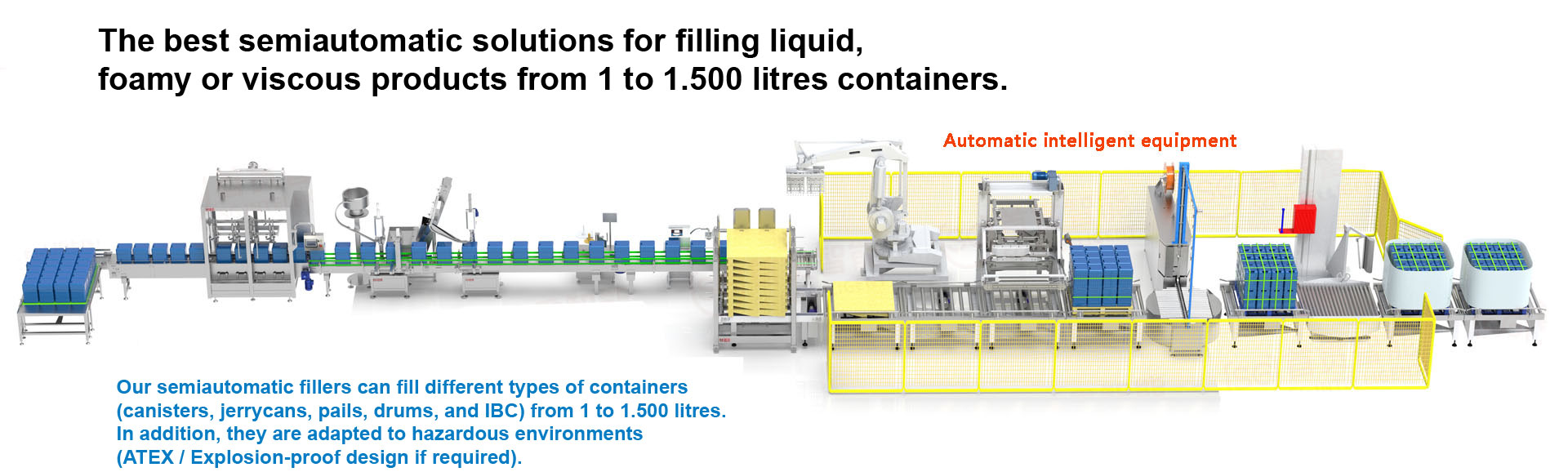

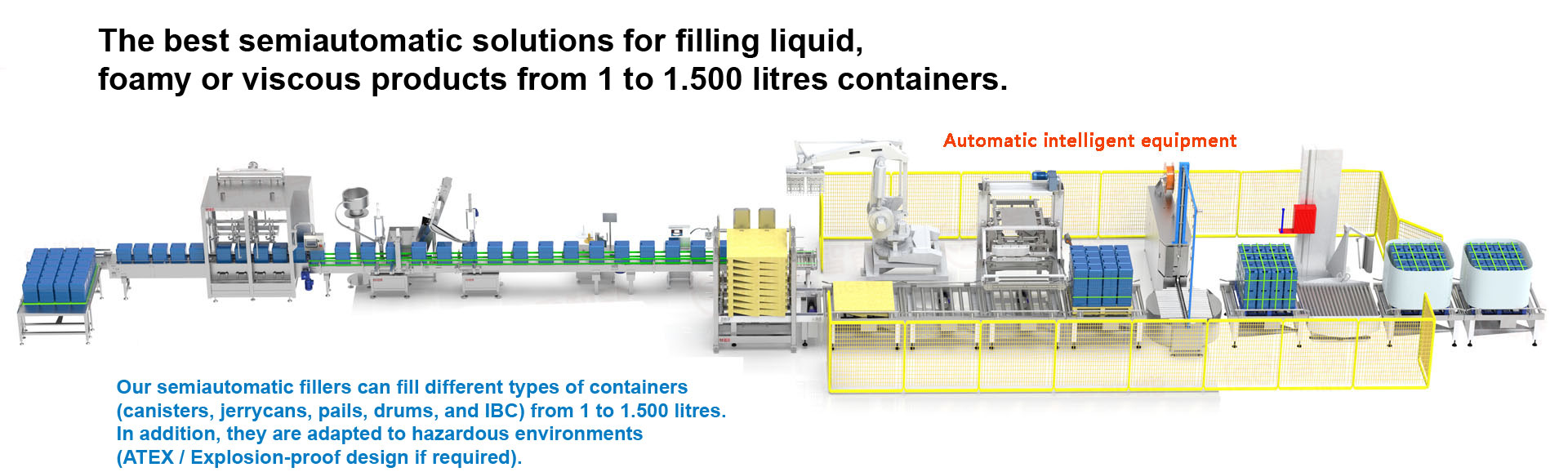

The 200L Dual-Head Liquid Filling Machine is a high-capacity, industrial-grade solution designed for efficient and precise filling of liquids, chemicals, oils, and other fluids into containers up to 200 liters. With its dual-head configuration, this machine can simultaneously fill two containers, doubling productivity while ensuring accuracy and consistency. Ideal for industries such as chemical manufacturing, food processing, pharmaceuticals, and bulk liquid packaging, it combines robust construction with advanced automation.

Key Features

Dual-Head Design

Parallel Filling: Two independent filling heads allow simultaneous filling of two containers, maximizing throughput.

Adjustable Heads: Customizable for different container sizes (e.g., drums, IBCs, or large bottles).

High-Capacity & Heavy-Duty Construction

200L Capacity: Handles large volumes per fill cycle (up to 200 liters per container).

Stainless Steel Frame: 304/316L stainless steel for corrosion resistance and durability in harsh environments.

ATEX Compliance: Suitable for hazardous or explosive atmospheres (optional).

Precision Filling Technology

Load Cell Weighing System: ±0.5% accuracy for consistent fill levels.

Flow Control: Variable speed filling with adjustable flow rates to prevent splashing or foaming.

Nozzle Design: Anti-corrosion, self-venting nozzles for clean, drip-free filling.

Automation & Efficiency

PLC Touchscreen Interface: Easy programming for fill volumes, speeds, and container types.

Automated Conveyor Integration: Seamlessly integrates with conveyor systems for continuous operation.

Batch Memory: Store settings for multiple products or container sizes.

Safety & Environmental Control

Spill Prevention: Vacuum or pressure filling options to minimize spills and fumes.

Dust & Fume Extraction: Integrated system for capturing airborne particles during filling.

Emergency Stop & Safety Sensors: Prevents overfilling and operator injury.

Customization Options

Material Compatibility: Suitable for acids, bases, solvents, oils, and viscous liquids.

Nitrogen Blanketing (Optional): Prevents oxidation or contamination during filling.

RFID/Barcode Reading: For tracking batches, expiration dates, or product identification.

Technical Specifications

Filling Range: 1–200 liters per container (adjustable in 0.1L increments).

Accuracy: ±0.5% of target volume.

Speed: Up to 60–120 containers/hour (depending on container size and liquid viscosity).

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Safety Rating: IP65 (dust and water resistant).

Material Compatibility: Stainless steel, optional Hastelloy or PTFE coatings for aggressive chemicals.

Operation Steps

Container Positioning: Automated conveyor aligns containers under the dual filling heads.

Pre-Weighing: The system checks the container weight before filling begins.

Filling: Dual heads dispense liquid at controlled flow rates, monitored by load cells.

Post-Weighing: Final weight verification ensures each container meets the target volume.

Sealing & Capping (Optional): Integrated sealing or capping modules secure containers after filling.

Discharge: Filled containers are transported downstream for labeling, palletizing, or storage.

Applications

Chemicals & Petrochemicals: Filling drums, IBCs, or tanks with solvents, acids, and bases.

Food & Beverage: Edible oils, syrups, sauces, and bulk liquid food products.

Pharmaceuticals: High-purity liquids, APIs, and sterile solutions.

Oils & Lubricants: Engine oils, hydraulic fluids, and greases.

Agriculture: Fertilizers, pesticides, and crop protection chemicals.

Industrial Cleaning: Detergents, disinfectants, and specialty cleaners.

Benefits

High Throughput: Dual-head design doubles productivity compared to single-head machines.

Versatility: Handles a wide range of liquids and container sizes with customizable settings.

Accuracy: Advanced weighing and flow control ensure precise fill volumes.

Safety: Hazardous area compliance and spill prevention protect operators and equipment.

Low Maintenance: Robust stainless steel construction and automated cleaning systems reduce downtime.

Scalability: Easily integrates with larger production lines or additional processes (e.g., capping, labeling).

Why Choose This Machine?

This 200L Dual-Head Liquid Filling Machine is built for industrial-grade reliability, combining speed, precision, and safety for high-volume liquid filling applications. Whether you need to package chemicals, oils, or food products, its heavy-duty design and advanced automation make it the ideal choice for demanding environments. Contact us for a tailored quote or consultation!

Immediate Order:

Website: http://www.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Automatic Mouth-Finding Filling Machine Is Suitable for Ink Solvent/Polyurethane Filling[2025-05-07]

-

200L Semi Auto Thinner Explosion-Proof Drum Filler Machine[2025-04-23]

-

Advanced 30L Explosion-Proof Emulsion and Paint Filling System[2025-04-28]

-

Semi-Automatic Disinfectant Pails Metering and Filling Machine for 25L[2025-05-09]