Heavy-Duty Ton Barrel Filling System for Efficient Production

Heavy-Duty Ton Barrel Filling System | Efficient, Reliable Solutions for High-Volume Production

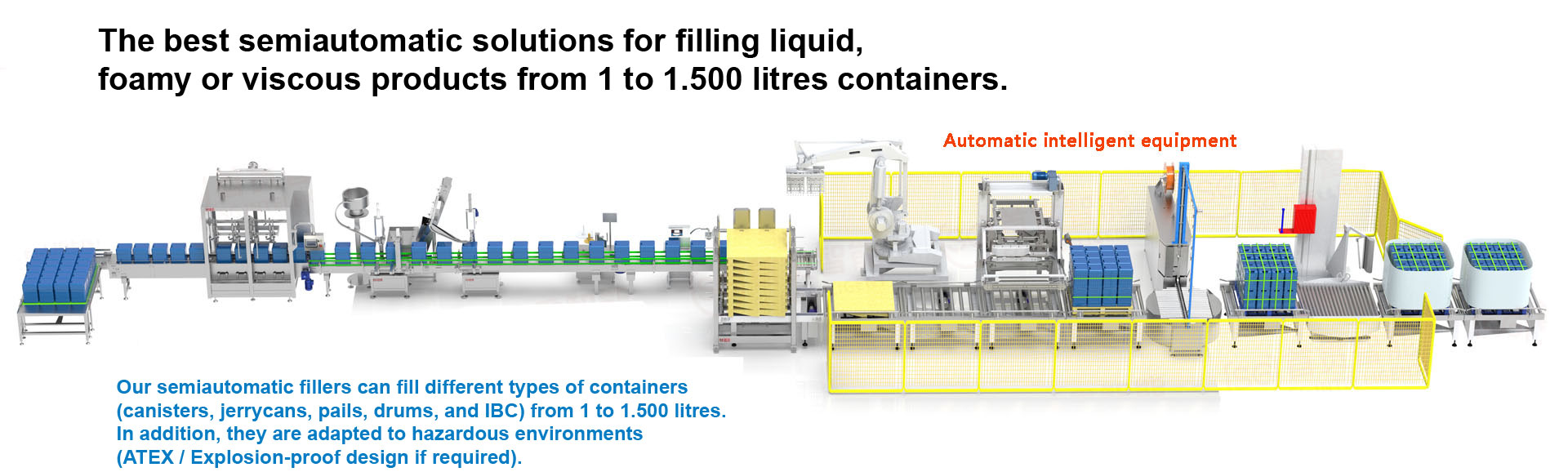

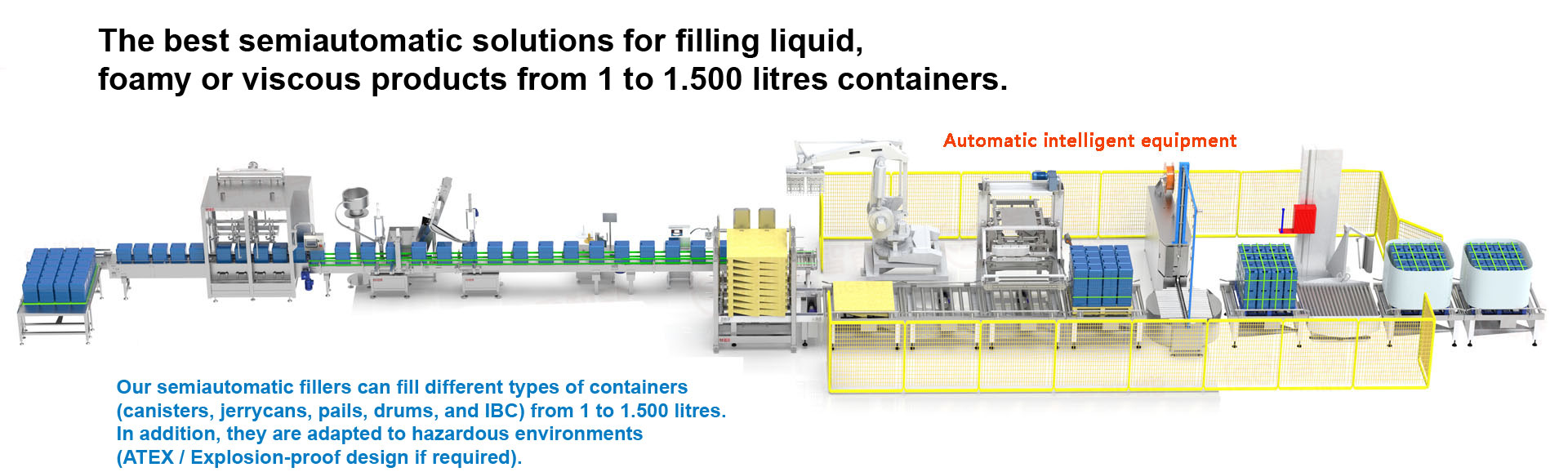

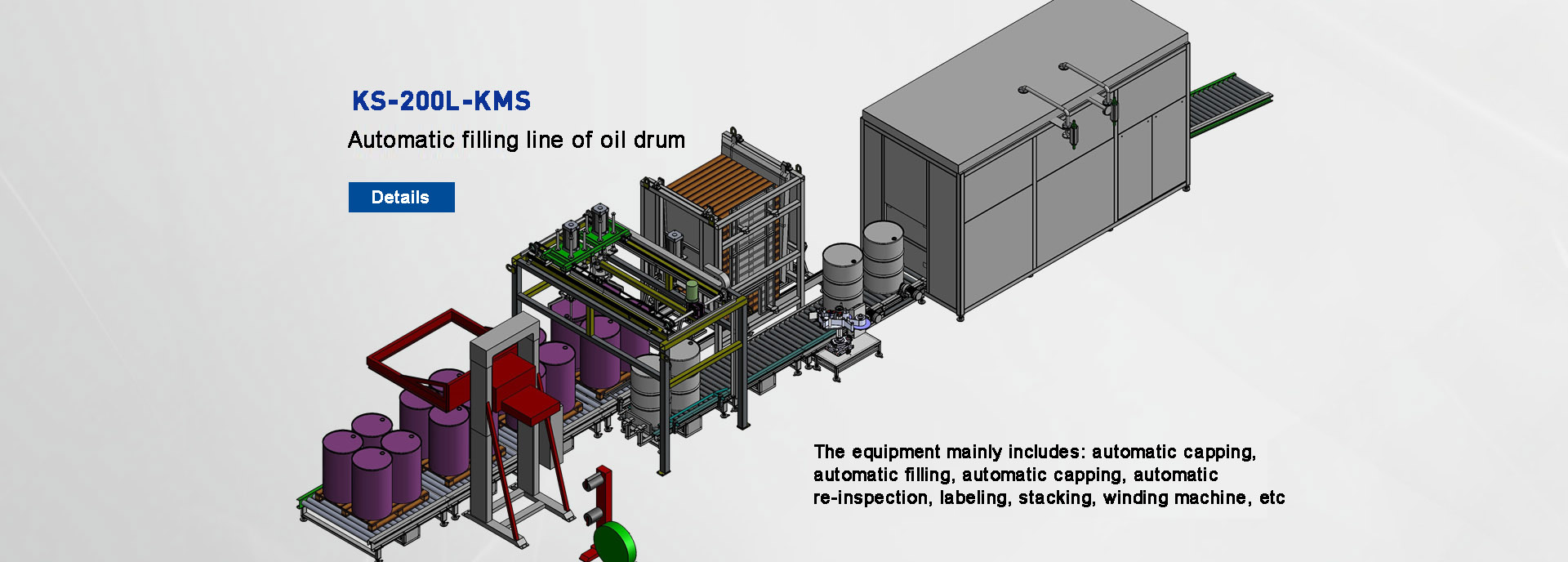

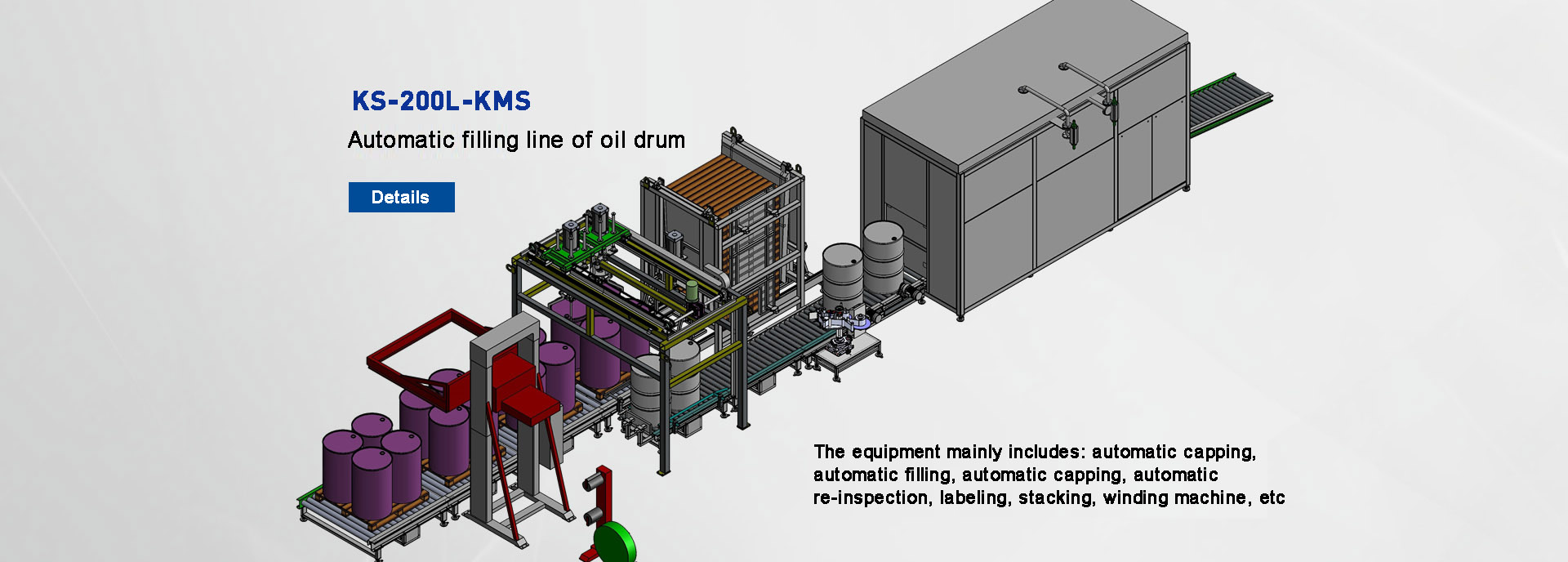

A Heavy-Duty Ton Barrel Filling System is designed to handle the rigorous demands of industrial environments, providing fast, precise, and safe filling of 200L, 208L (IBC), or 1000L ton barrels. Ideal for chemicals, oils, lubricants, food products, and more, these systems optimize production workflows while minimizing labor, product loss, and environmental risks.

Key Features

High-Speed Efficiency

Adjustable fill speeds: Capable of filling a 200L barrel in 3–15 minutes (customizable based on product viscosity and nozzle size).

Dual-head or multi-nozzle options for simultaneous filling of multiple barrels, reducing cycle times.

Precision Control

Weight-based or volumetric filling with ±0.5% accuracy (upgradeable to ±0.2%).

Load cells + flow meters for real-time monitoring and automatic shutoff at target weight/volume.

Temperature compensation to account for thermal expansion in sensitive liquids.

Robust Construction

Stainless steel (304/316) frame and contact parts for corrosion resistance and compatibility with aggressive chemicals.

Pneumatic or electric actuators for reliable valve operation in harsh conditions.

Forklift-compatible designs with adjustable stands for easy loading/unloading of barrels.

Safety & Compliance

ATEX/NFPA/OSHA compliant for hazardous environments (e.g., flammable liquids, explosive atmospheres).

Drip-free valves, static grounding clamps, and emergency stop buttons to prevent spills and operator injury.

Inert gas blanketing option to eliminate vapor buildup and oxidation during filling.

Automated Operation

Touchscreen HMI with pre-programmable recipes, batch tracking, and diagnostic alerts.

Remote monitoring via Ethernet/USB and data logging for traceability and compliance.

Interlocked safety guards to prevent accidental operation during maintenance.

Customization Options

Viscosity-specific pumps (centrifugal, gear, diaphragm) for thin to high-viscosity liquids.

Nozzle adapters for various barrel spout sizes and shapes (e.g., round, oval, or custom ports).

Integrated weighing scales or RFID tagging for inventory management.

Benefits

Production Throughput: Reduces labor costs and cycle times with automated, high-speed filling.

Accuracy: Minimizes product giveaway and ensures consistent batch weights/volumes.

Safety: Prevents operator exposure to hazardous fumes, spills, or manual handling.

Flexibility: Handles multiple container types (barrels, IBCs, drums) and liquid viscosities.

ROI: Payback period typically under 1 year due to labor savings and reduced product loss.

Technical Specifications

Capacity: Up to 200L/min (adjustable based on pump and nozzle size).

Accuracy: ±0.5% to ±0.2% (weight-based or volumetric).

Materials: Stainless steel (304/316), Hastelloy, or PTFE (for corrosive products).

Power: 220V/380V/480V (customizable for regional standards).

Environment: ATEX Zone 1/21 or NEMA 4/4X for harsh or explosive environments.

Communication Ports: Ethernet, USB, or industrial protocols (e.g., Profibus, Modbus).

Applications

Chemicals: Acids, bases, solvents, resins, and bulk chemicals.

Oil & Lubricants: Engine oils, hydraulic fluids, greases, and specialty lubricants.

Food & Beverage: Syrups, oils, sauces, and bulk liquid ingredients.

Pharmaceuticals: APIs, bulk actives, and liquid formulations.

Industrial Cleaning: Solvents, degreasers, and bulk cleaning agents.

Why Choose a Heavy-Duty Ton Barrel Filler?

Reliability: Industrial-grade components ensure continuous operation in demanding environments.

Scalability: Modular designs allow for future upgrades (e.g., additional pumps, automation features).

Support: OEM warranties, spare parts availability, and global service networks.

Compliance: Fully meets ATEX, NFPA, OSHA, and GMP standards for hazardous and hygienic applications.

Integration Capabilities

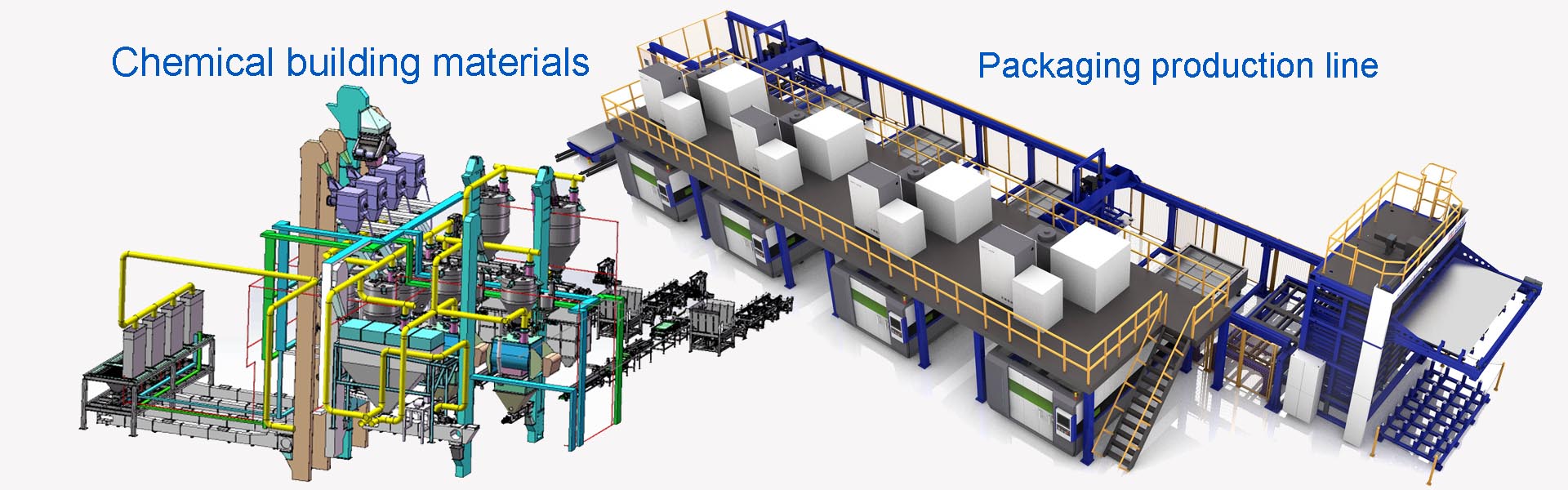

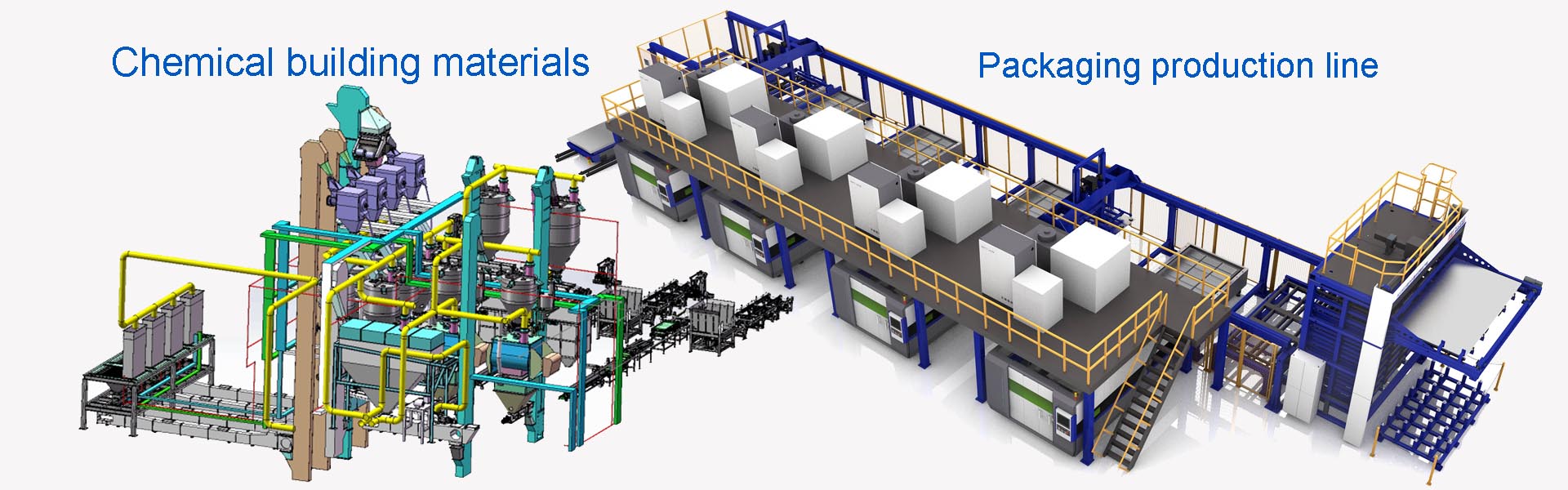

Upstream: Connects with mixing tanks, blenders, or storage vessels via pumps or gravity feed.

Downstream: Seamlessly integrates with palletizing systems, labeling machines, or automated warehouse logistics.

Smart Factory: Compatible with Industry 4.0 platforms for remote monitoring, predictive maintenance, and data analytics.

Ideal For

Industries requiring high-throughput, low-risk filling of ton barrels, including:

Chemical manufacturers and distributors.

Oil and lubricant producers.

Food and beverage processors.

Pharmaceutical formulators.

Industrial cleaning and water treatment facilities.

Invest in a Heavy-Duty Ton Barrel Filling System to maximize efficiency, safety, and precision in your high-volume production lines.

Immediate Order:

Website: http://www.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com