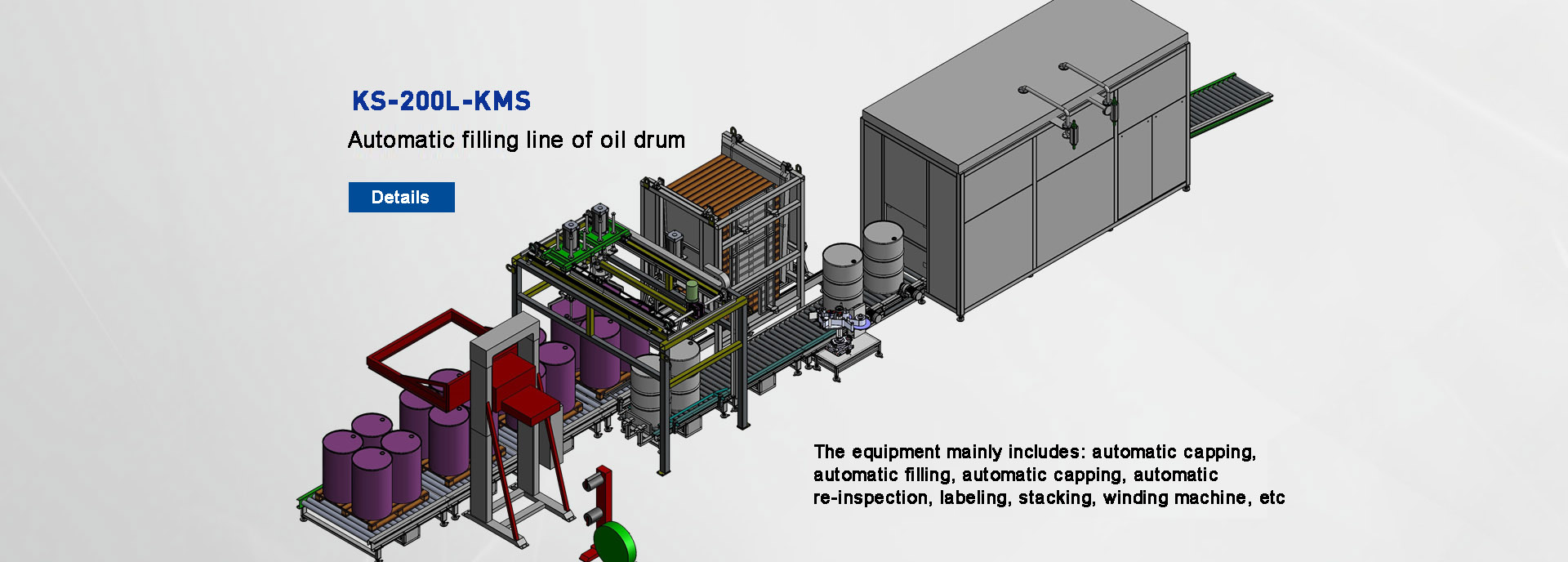

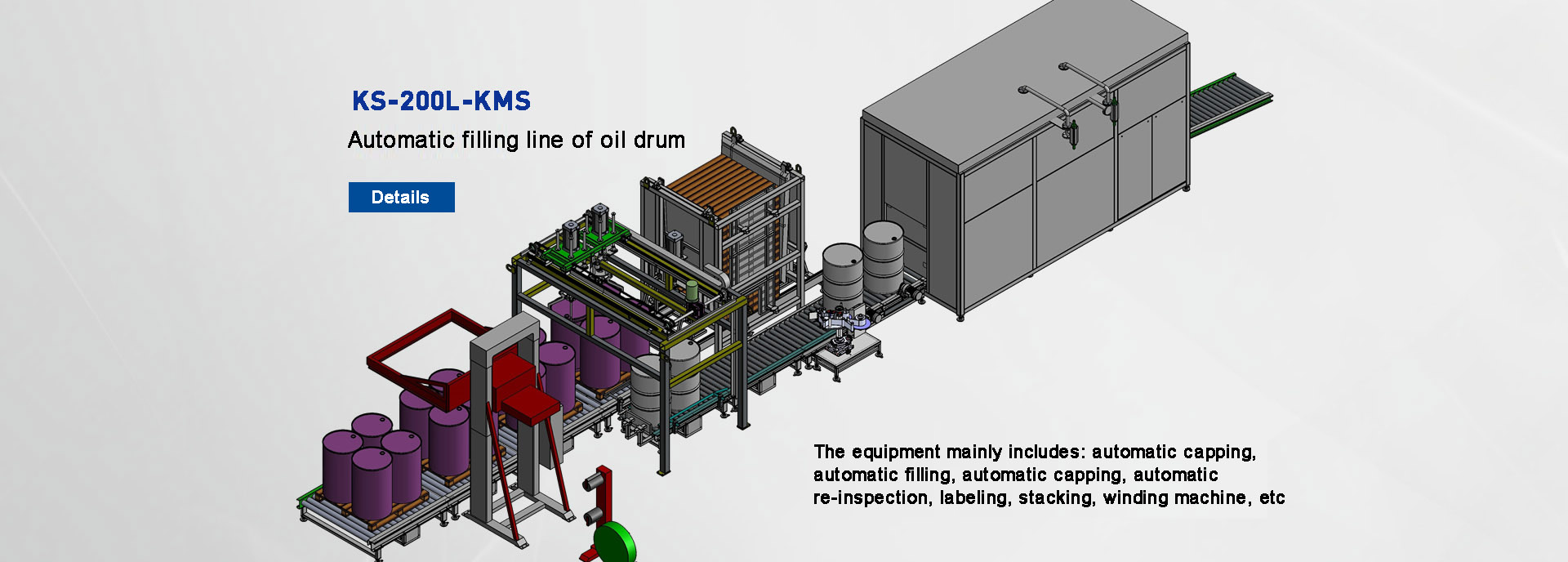

Industrial 200L Drum Filling Machine for Chemicals and Engine Oil

Industrial 200L Drum Filling Machine for Chemicals & Engine Oil

Overview

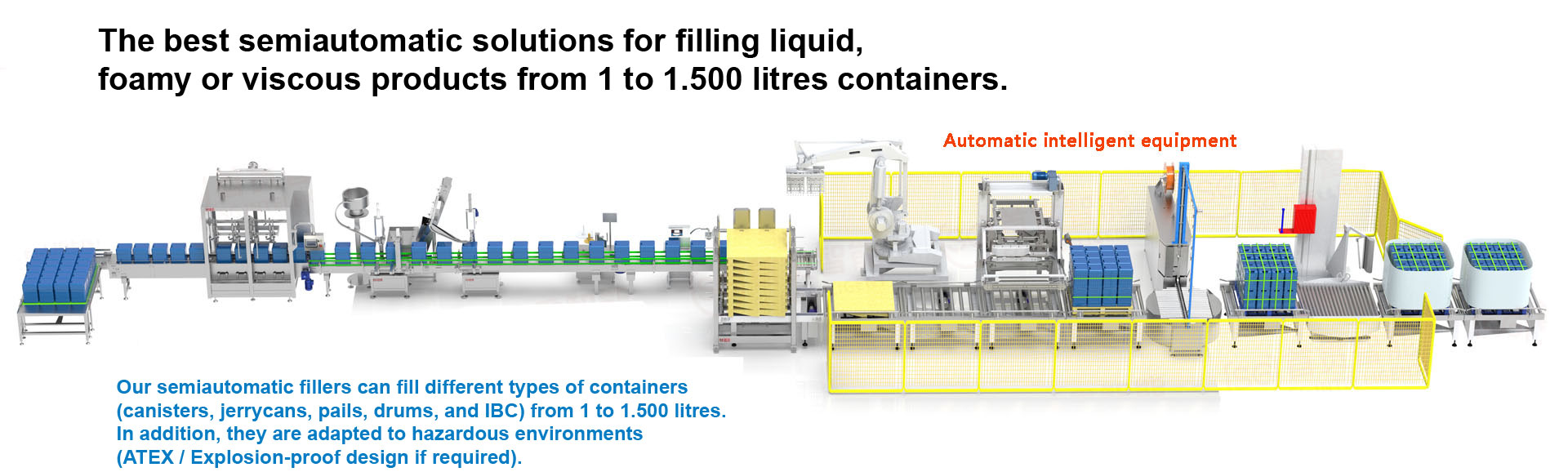

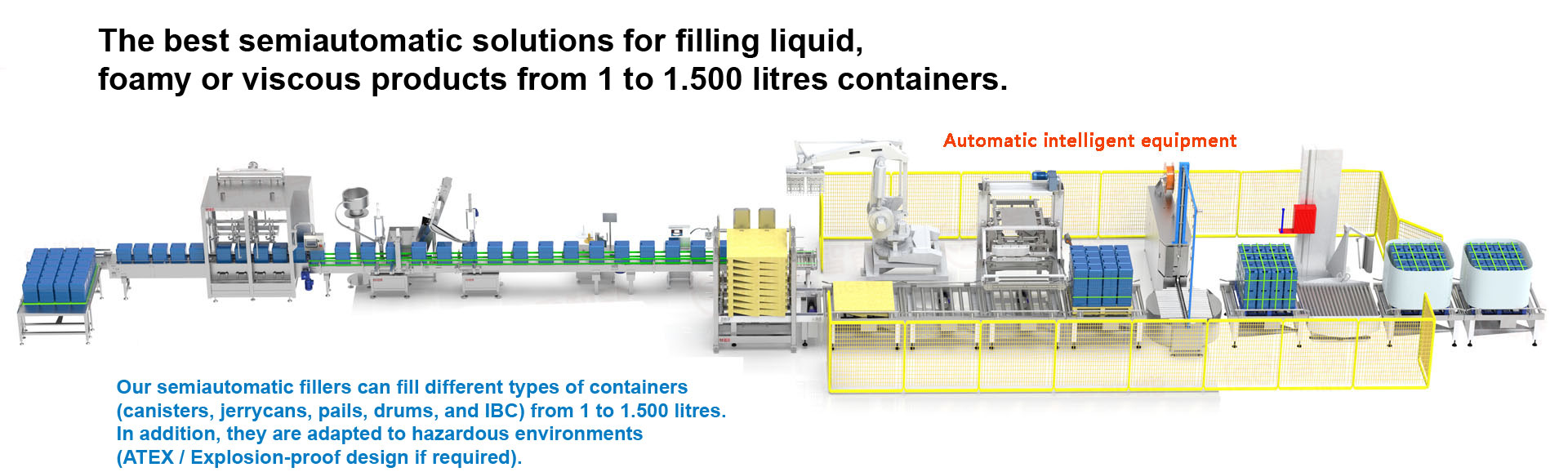

The 200L Drum Filling Machine is a heavy-duty, automated solution designed for high-volume filling of industrial chemicals, engine oils, lubricants, and other liquids. With precise flow control, explosion-proof components, and compatibility with hazardous materials, it ensures safe, efficient, and accurate drum filling in industrial environments.

Key Features

High Accuracy & Speed

Precision Filling: ±0.2% accuracy (adjustable) with flow meters and weight-based systems.

Fast Throughput: Up to 60–120 drums/hour (depends on viscosity and product).

Material Compatibility

Chemicals: Stainless steel (304/316L) or carbon steel construction with chemical-resistant coatings.

Engine Oil: Robust gear pumps handle high viscosities (up to 2000 cSt).

Safety & Compliance

Explosion-Proof: ATEX/IECEx certification for Class II, Division 1 hazardous locations.

Drum Grounding: Automated grounding system prevents static buildup.

Leak Detection: Integrated sensors flag leaks or spills during operation.

Automation & Ease of Use

Touchscreen HMI: Intuitive interface for setting fill volumes, speeds, and recipes.

Semi-Automatic Design: Manual drum placement with automated filling, splash-proof nozzles, and auto-stop.

Remote Control: Option to start/stop cycles from a distance (ideal for hazardous zones).

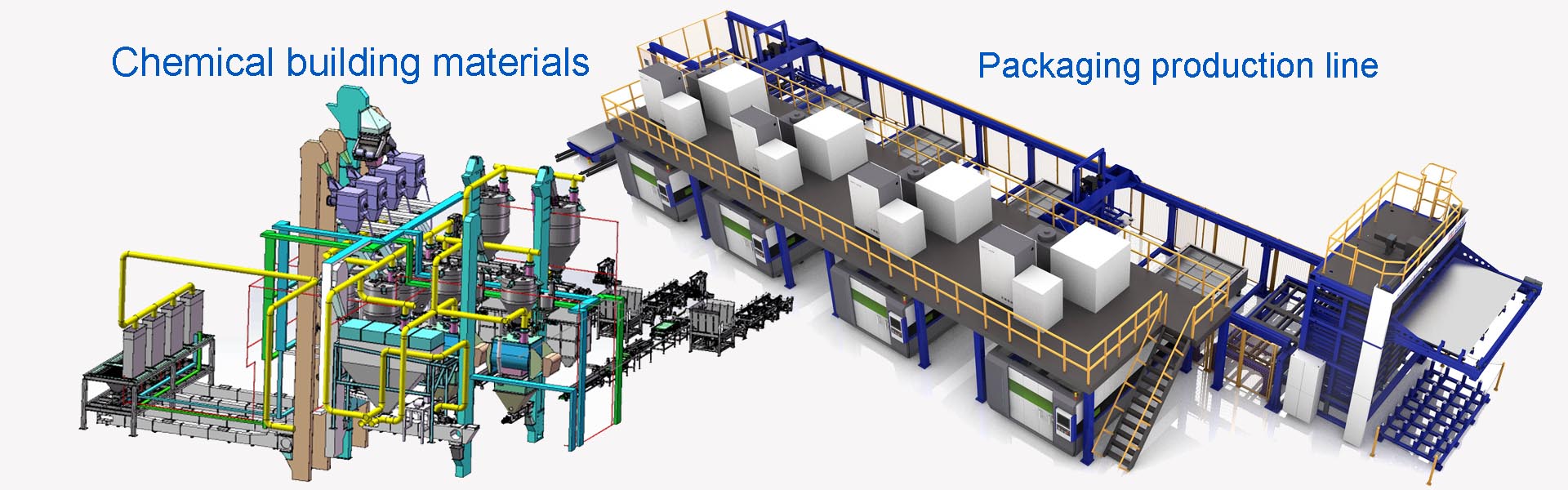

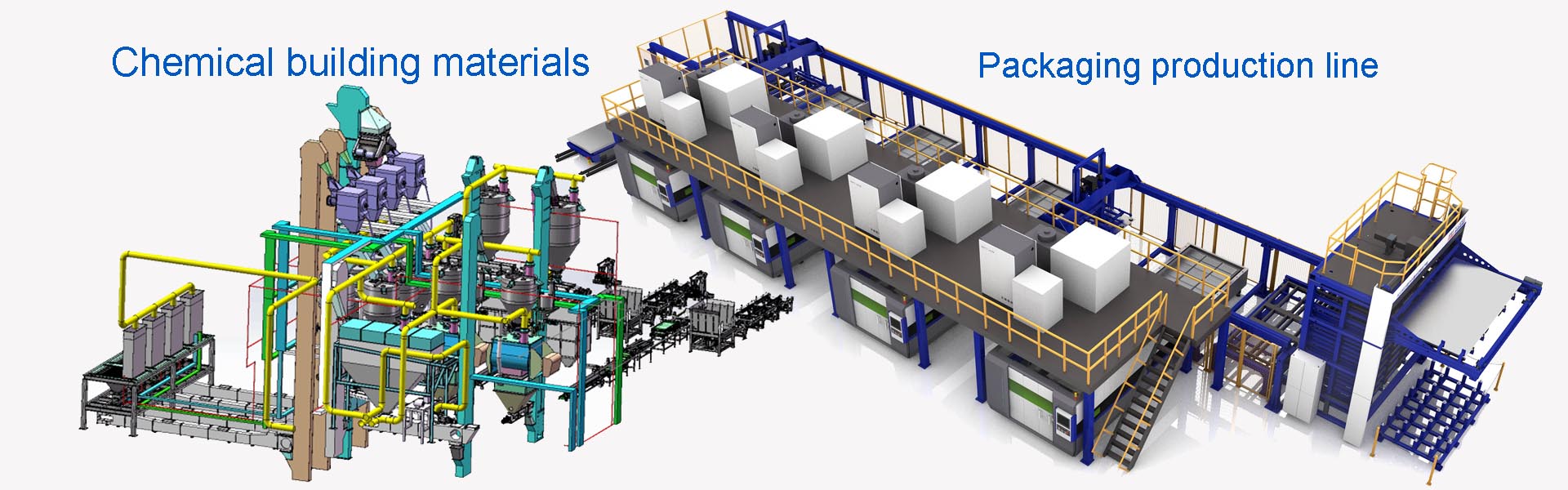

Versatile Integration

Customizable Nozzles: For different drum sizes (e.g., 200L, 100L, or IBC totes).

Conveyor Systems: Optional roller or belt conveyors for seamless drum handling.

Weighing Scales: Integrated or standalone scales for net weight verification.

Technical Specifications

Filling Capacity: 200 liters per drum (customizable for smaller/larger volumes).

Accuracy: ±0.1–0.2% (weight-based or volumetric).

Materials:

Chemical Compatibility: PTFE seals, stainless steel, or Hastelloy (for aggressive chemicals).

Oil & Lubricants: High-viscosity pumps with optional heating elements (for cold climates).

Power: 220V/50Hz or 110V/60Hz (explosion-proof motors).

Certifications: CE, ATEX, ISO, and OIML-R60 for weighing modules.

Applications

Chemicals: Acids, solvents, adhesives, resins, and industrial fluids.

Automotive: Engine oils, gear oils, coolants, and greases.

Lubricants: Industrial oils, hydraulic fluids, and specialty lubricants.

Food Grade: Edible oils and non-hazardous food additives (with appropriate material upgrades).

Operation Steps

Drum Placement: Position a 200L drum under the filling nozzle (manually or via conveyor).

Auto Grounding: Drum is automatically grounded to eliminate static risks.

Precision Filling: The machine dispenses the product while monitoring weight or flow rate.

Auto Stop: Filling stops automatically at the preset volume, avoiding overfill.

Seal & Move: Optionally apply a tamper-evident seal and move the drum via conveyor.

Optional Features

Nitrogen Overlay: Prevents oxidation and foaming in sensitive products (e.g., oils).

Data Logging: USB/Ethernet export of fill records for traceability.

Vapor Recovery: Enclosed system with carbon filters for hazardous fumes.

Heating Jackets: For cold environments or high-viscosity products.

RFID Tracking: Links drums to batch numbers for inventory management.

Benefits

Safety First: Explosion-proof design and static control ensure operator and site safety.

Regulatory Compliance: Meets global standards for hazardous materials and industrial use.

Reduced Labor Costs: Automated filling minimizes manual intervention.

Minimal Waste: Accurate filling reduces product giveaway and environmental impact.

Longevity: Heavy-duty construction withstands continuous industrial use.

Why Choose This Machine?

This 200L Drum Filling Machine combines precision, safety, and automation to handle demanding industrial applications. Whether you’re filling corrosive chemicals or viscous oils, its customizable design and robust features ensure reliable performance in harsh environments.

Request a quote today for tailored solutions!

-

High-Speed Auto Drum Filling Machine for Chemical Liquids[2025-04-28]

-

Fully Automatic Vat Glacial Acetic Acid Weighing Filling Machine for 200L[2025-05-15]

-

High Efficiency Automatic Ketchup Sauce Filling Machine Line[2025-03-29]

-

Stainless Steel 200L Automatic Liquid Filler with Touch Screen - Intelligent Bottling Machine for Food Pharma Chemical[2025-05-13]