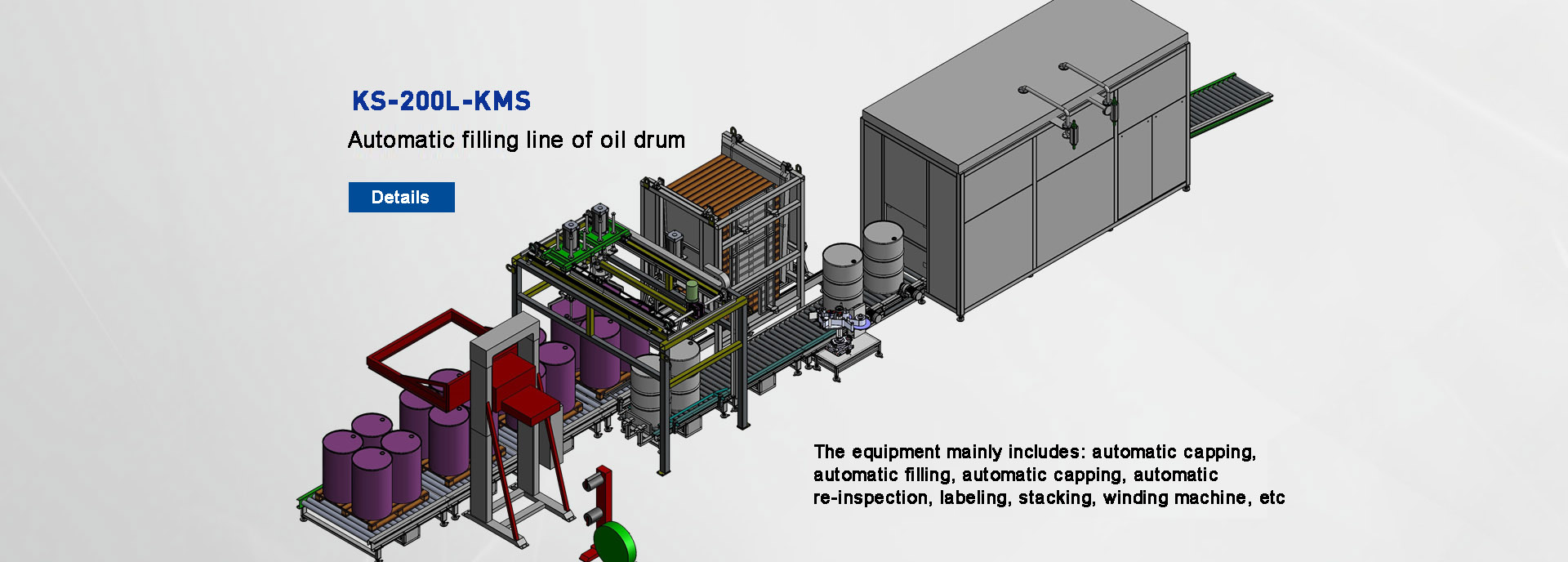

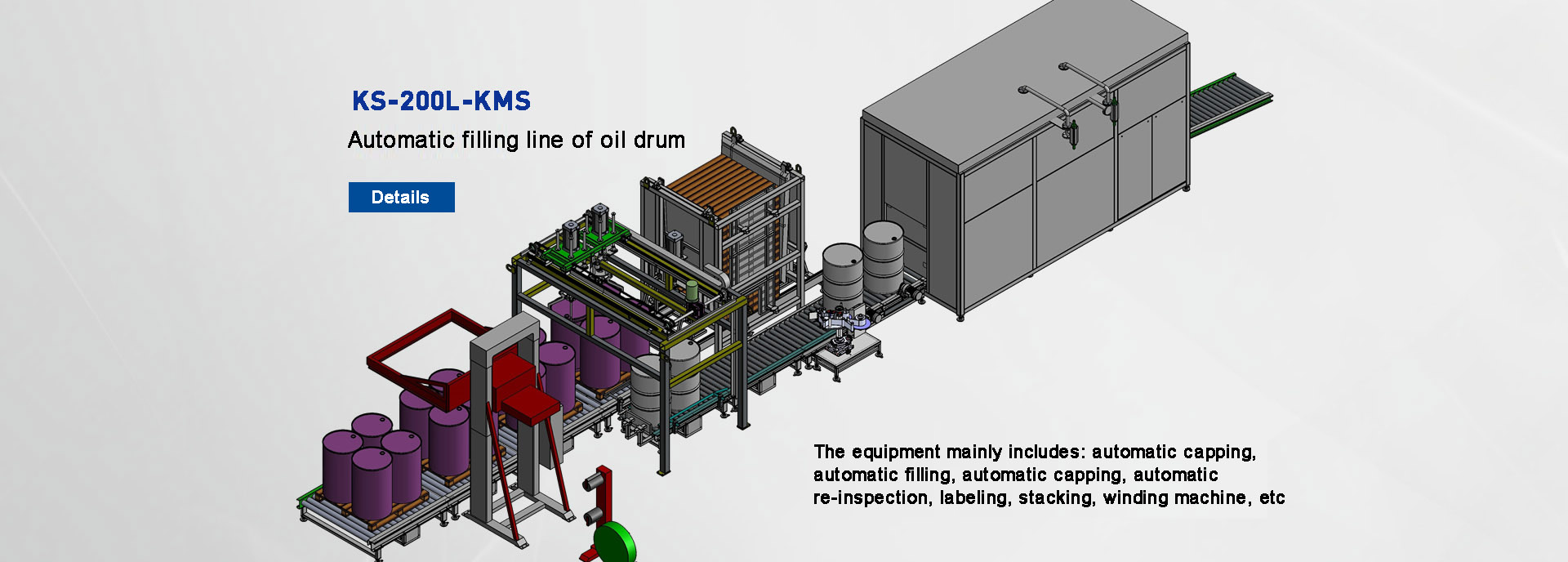

416 Stainless Steel Phosphoric Acid Filling Machine Is Used to Fill 200L Formic Acid

A 416 Stainless Steel Phosphoric Acid Filling Machine designed to fill 200L drums of formic acid requires careful consideration of material compatibility, safety, and precision. Below is a detailed overview of the machine’s features, benefits, and key considerations for this application:

Key Features:

Material Compatibility:

Viton or PTFE Seals: Prevents deterioration from prolonged exposure to formic acid.

High-Density Polyethylene (HDPE) or PVDF Hoses: Resists chemical attack and ensures safe fluid transfer.

Resistance to Corrosion: 416 stainless steel is specifically chosen for its excellent resistance to corrosive acids like phosphoric and formic acid, ensuring longevity and reliability.

Strength and Durability: Suitable for handling high-acidity chemicals without degradation.

416 Stainless Steel Construction:

Chemical-Resistant Hoses and Seals:

Weighing System (Gravimetric Filling):

Measures and subtracts the weight of empty drums to ensure precise net filling.

Ensures accurate filling with ±50g to ±100g precision for 200L drums.

Real-time weight monitoring prevents overfilling or underfilling.

High-Precision Load Cells:

Tare Weight Calibration:

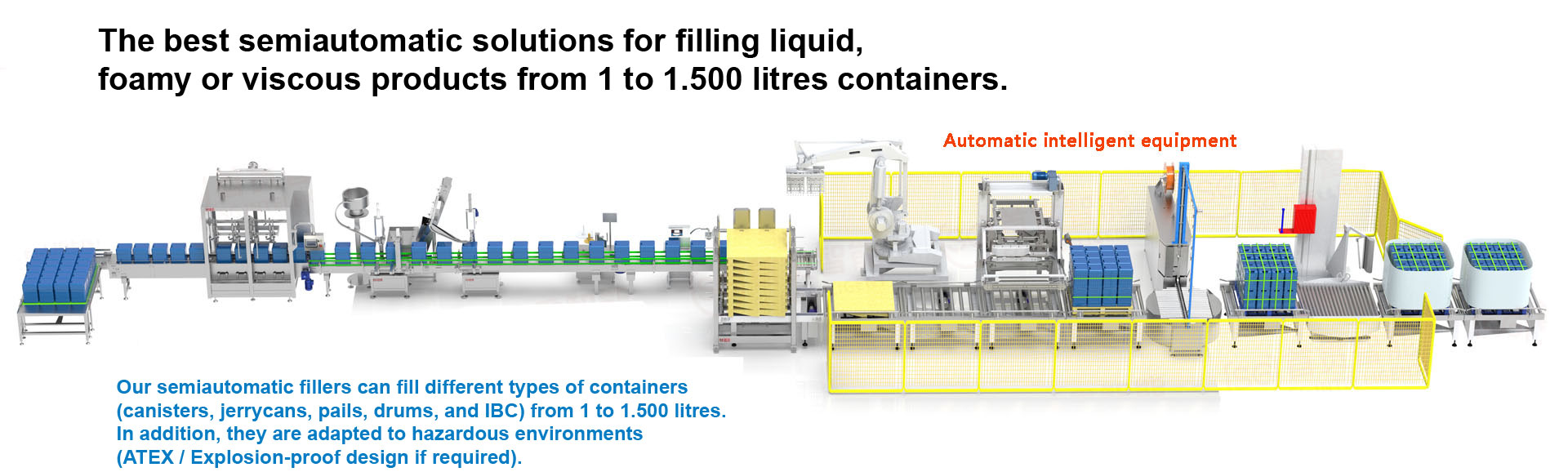

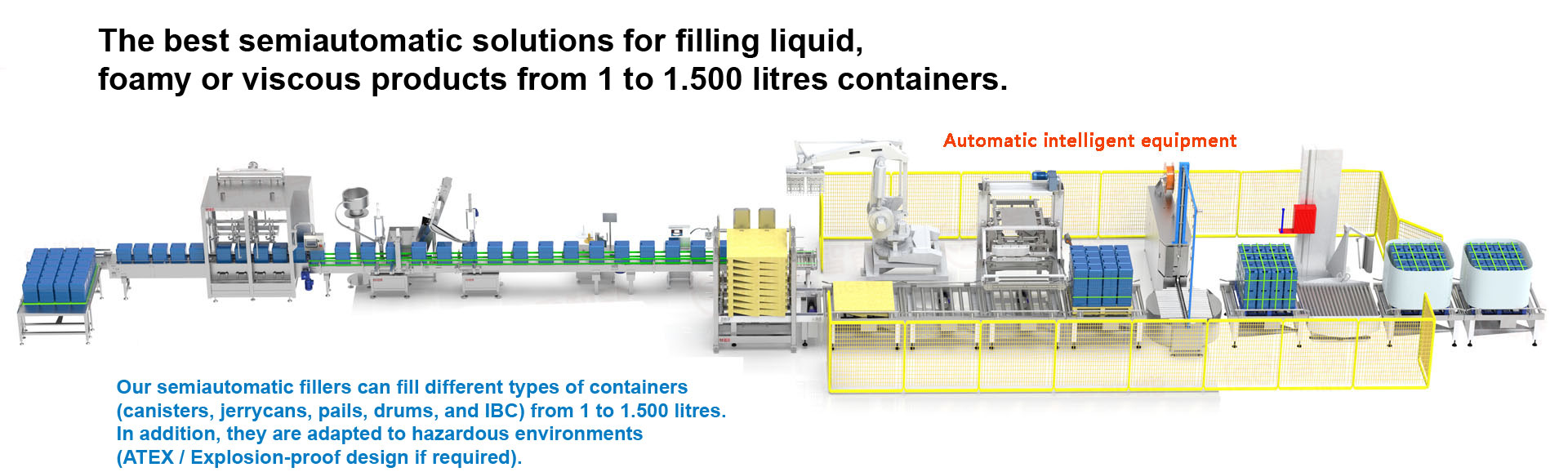

Semi-Automatic Operation:

Store multiple filling parameters for different products or drum sizes.

Start/stop functionality allows the operator to initiate and stop filling manually, combining automation with manual oversight.

Foot pedal or button control enables hands-free operation.

Operator Control:

Pre-Set Recipes:

Safety Features:

Quickly halts operation in case of emergencies.

Prevents accidental operation when not in use.

Integrated exhaust system to handle volatile fumes from formic acid.

Minimizes leaks and spills during filling, ensuring easy cleanup.

Drip Trays and Spill Containment:

Fumes Extraction (Optional):

Lockable Guards:

Emergency Stop:

High Viscosity Handling (If Needed):

Controls flow rate to prevent splashing or foaming.

Ensures smooth filling of viscous fluids (if formic acid has higher viscosity).

Positive Displacement Pump:

Adjustable Filling Speed:

Customization Options:

Automates drum transport to downstream processes like capping or labeling.

Adds batch numbers, expiration dates, or barcodes to drums for traceability.

Inert gas purging to prevent oxidation or foaming of formic acid during filling.

Nitrogen Blanketing (Optional):

Labeling/Coding Systems:

Conveyor Integration:

User-Friendly Interface:

Shows real-time weight, target weight, and fill status.

Easy to set target weights, monitor fill progress, and access historical data.

Touchscreen Control Panel:

LED Display:

Maintenance and Durability:

Designed to handle corrosive fluids with minimal wear.

Stainless steel parts and removable hoses simplify cleaning.

Easy-to-Clean Components:

Long-Life Pump and Valves:

Benefits:

Corrosion Resistance:

416 stainless steel and chemical-resistant components ensure long-term durability in harsh acidic environments.

Precision Filling:

Gravimetric weighing ensures accurate fill volumes, reducing product waste and ensuring consistency.

Safety:

Spill containment, fumes extraction, and lockable guards protect operators and prevent accidents.

Efficiency:

Semi-automatic operation reduces labor costs compared to manual filling while maintaining control.

Versatility:

Can be customized for other corrosive acids (e.g., sulfuric acid, hydrochloric acid) if needed.

Cost-Effective:

Affordable compared to fully automatic systems while still delivering high accuracy and efficiency.

Applications:

Formic Acid Filling:

Filling 200L drums of formic acid for industrial or commercial use.

Phosphoric Acid Filling:

Filling drums of phosphoric acid for agricultural or chemical applications.

Other Corrosive Acids:

Suitable for filling other corrosive acids like sulfuric acid, hydrochloric acid, or nitric acid.

Specialty Chemicals:

Filling drums of other high-purity or corrosive liquids.

Operation Steps:

Drum Placement:

The operator places an empty 200L drum under the filling head using a pallet truck or forklift.

Tare Weight Calibration:

The machine measures the weight of the empty drum and subtracts it from the target fill weight.

Filling:

The operator starts the filling process via a foot pedal or button.

The pump dispenses formic acid into the drum while the weighing system continuously monitors the weight.

Filling stops automatically when the target weight is reached.

Sealing/Capping (Optional):

After filling, the operator manually places a lid or cap on the drum and tightens it securely.

Discharging:

The filled drum is moved to the next stage (e.g., labeling, palletizing) manually or with a conveyor system.

Cleanup:

Drip trays and sealed components minimize spills, keeping the machine and work area clean.

Considerations When Purchasing:

Chemical Compatibility:

Ensure all components (steel grade, hoses, seals) are compatible with formic acid and any other chemicals being filled.

Accuracy Requirements:

Choose a weighing system with the required precision (e.g., ±50g for 200L drums).

Output Needs:

Select a model with the appropriate speed (e.g., 10–20 drums per hour) based on your production volume.

Customization Needs:

Consider additional features like nitrogen blanketing, coding systems, or integration with other equipment.

Budget:

Semi-automatic machines offer a cost-effective balance between manual and fully automatic systems.

Training and Maintenance:

Ensure the machine is easy to operate and maintain, with accessible spare parts.

Safety Regulations:

Ensure the machine complies with local safety standards for handling corrosive acids.

Why Choose This Machine?

This 416 stainless steel phosphoric acid filling machine is ideal for safely and accurately filling 200L drums of formic acid. Its corrosion-resistant construction, precision weighing system, and safety features make it a reliable choice for handling harsh chemicals. With optional features like nitrogen blanketing and coding systems, it can be tailored to meet specific production needs, ensuring efficiency, safety, and compliance in your operations.

Immediate Order:

Website: http://www.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com