New Product Piston Fully Automatic Honey Lqiuid Filling Machine

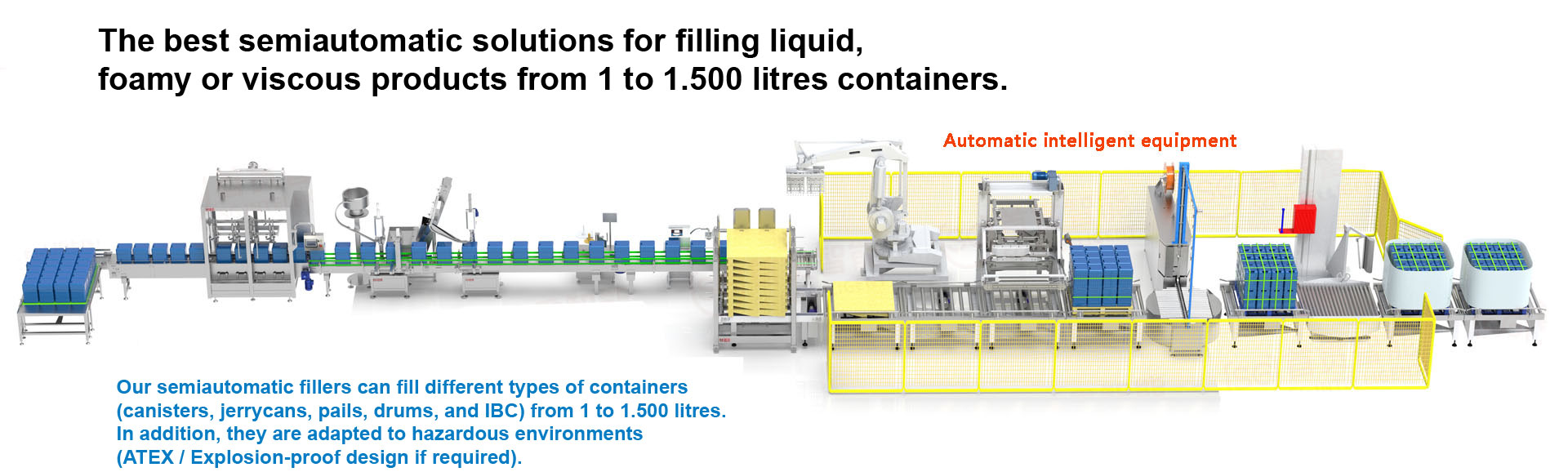

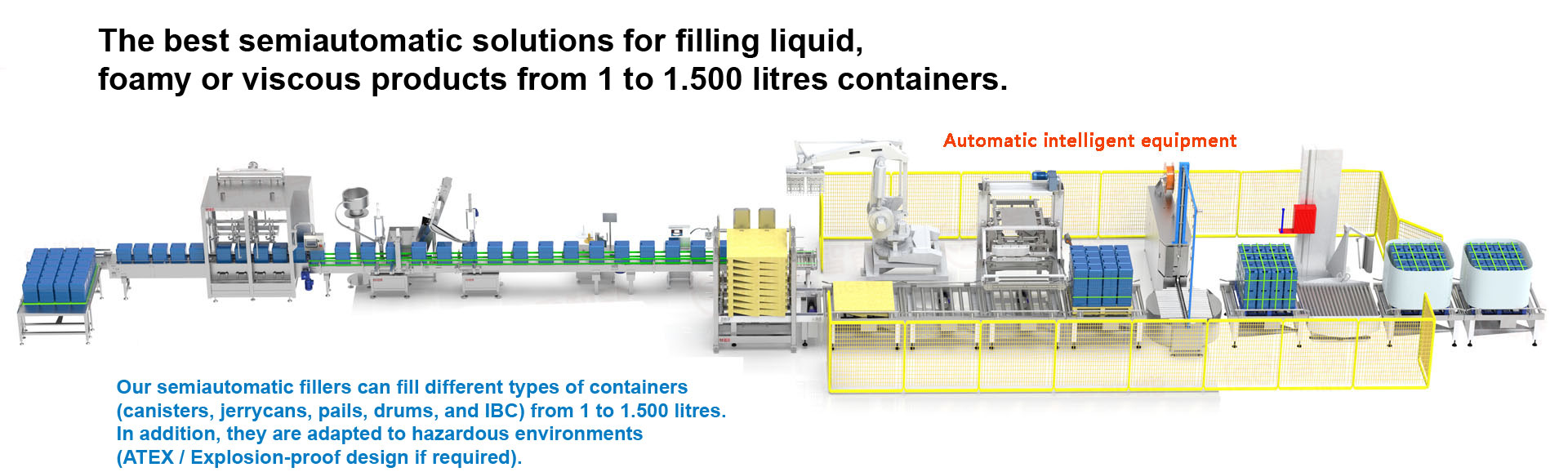

Introducing the New Product Piston Fully Automatic Honey Liquid Filling Machine, a cutting-edge solution designed for precision, efficiency, and versatility in liquid filling operations. Whether you're producing honey, beverages, chemicals, or engine oils, this machine is engineered to meet your needs with advanced features and robust performance.

Key Features & Benefits:

1. Fully Automatic Operation:

Automated Container Handling:

The machine automatically positions containers (bottles, jars, pouches, or barrels) under the filling nozzle using conveyors or robotic systems.

Touchscreen Control Panel:

Intuitive interface for easy setup and adjustment of fill volumes, speeds, and other parameters.

Remote Monitoring:

Optional integration with SCADA systems for real-time data tracking and analysis.

2. High-Precision Piston Filling Technology:

Volumetric Accuracy:

Ensures precise fill volumes (±0.5% accuracy) for liquids of varying viscosities, from thin beverages to thick honey or greases.

Adjustable Filling Speed:

Customizable flow rates to accommodate different products and container sizes.

No Overfilling:

Automatically stops filling once the preset volume is reached, preventing spills and product waste.

3. Versatile Compatibility:

Multiple Container Types:

Designed for bottles, jars, pouches, bags, barrels, and drums.

Wide Range of Products:

Suitable for honey, beverages, chemicals, tobacco extracts, engine oils, lubricants, and more.

Custom Nozzles:

Interchangeable nozzles for different container types and fill heights.

4. Safety & Environmental Protection:

Spill-Proof Design:

Minimizes drips and leaks during filling, keeping the work area clean.

Fumes Extraction System:

Optionally integrates with a fumes extraction system to vent harmful vapors away from the operator.

Grounding & Earthing:

Ensures static electricity is safely discharged, reducing the risk of sparks in hazardous environments.

Emergency Stop Function:

Instantly halts operation in case of emergencies.

5. Robust Construction:

Stainless Steel Materials:

Corrosion-resistant components ensure longevity and compatibility with aggressive chemicals.

Chemical Resistance:

All parts are made from materials that withstand exposure to acids, bases, and solvents.

6. Easy Maintenance & Cleaning:

Removable Parts:

Hopper, nozzles, and other components are easily detachable for cleaning and maintenance.

CIP (Clean-In-Place) Compatibility:

Optional integration for automated cleaning cycles.

Low Maintenance Costs:

Robust construction minimizes the need for frequent repairs or replacements.

Optional Add-Ons:

Weight Monitoring System:

Provides real-time feedback on fill volumes for accuracy.

Data Logging & Reporting:

Records production metrics for traceability and quality control.

Conveyor Belt Integration:

Streamlines the filling process by automatically moving containers.

Viscosity Control:

Adjusts flow rate for thicker or thinner products.

Capping & Sealing System:

Automatically seals bottles, jars, or pouches after filling.

Leak Detection System:

Alerts operators to any spills or leaks during filling.

Custom Nozzles:

For different container sizes and shapes.

Drum Roller Conveyor:

For easy movement of heavy barrels or drums.

Inert Gas Blanketing:

Prevents oxidation or contamination of sensitive products.

RFID Tracking:

For container identification and traceability.

Applications:

Honey Production:

Efficiently fills honey into jars, bottles, or pouches with precision.

Beverage Industry:

Filling juices, syrups, sodas, and other beverages into bottles or pouches.

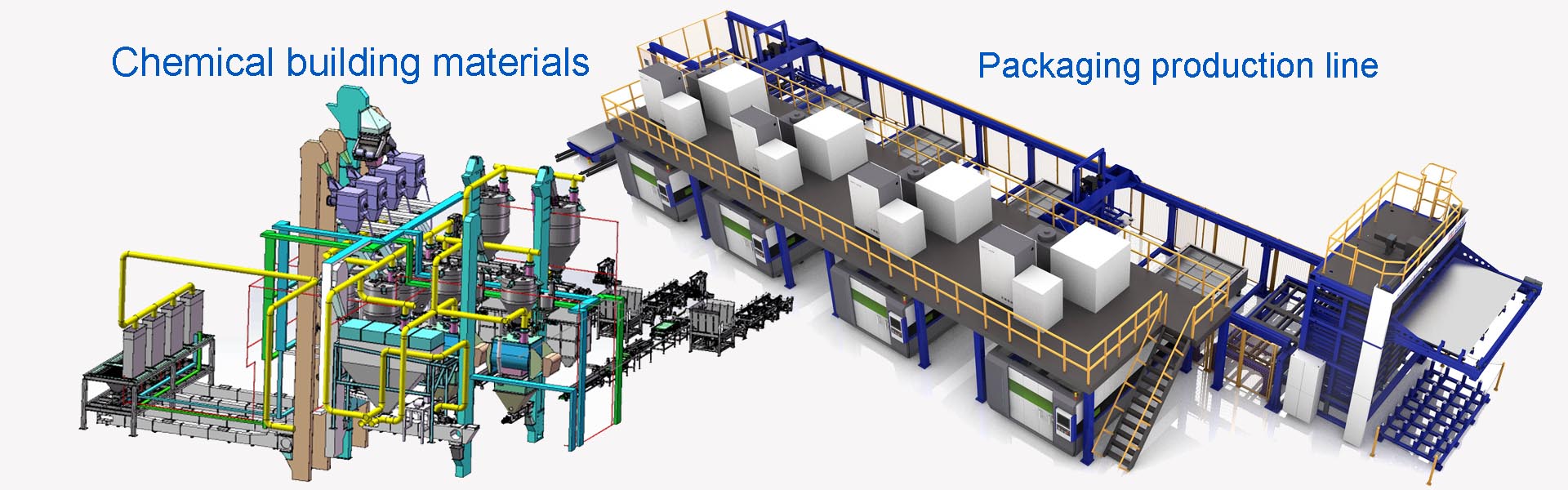

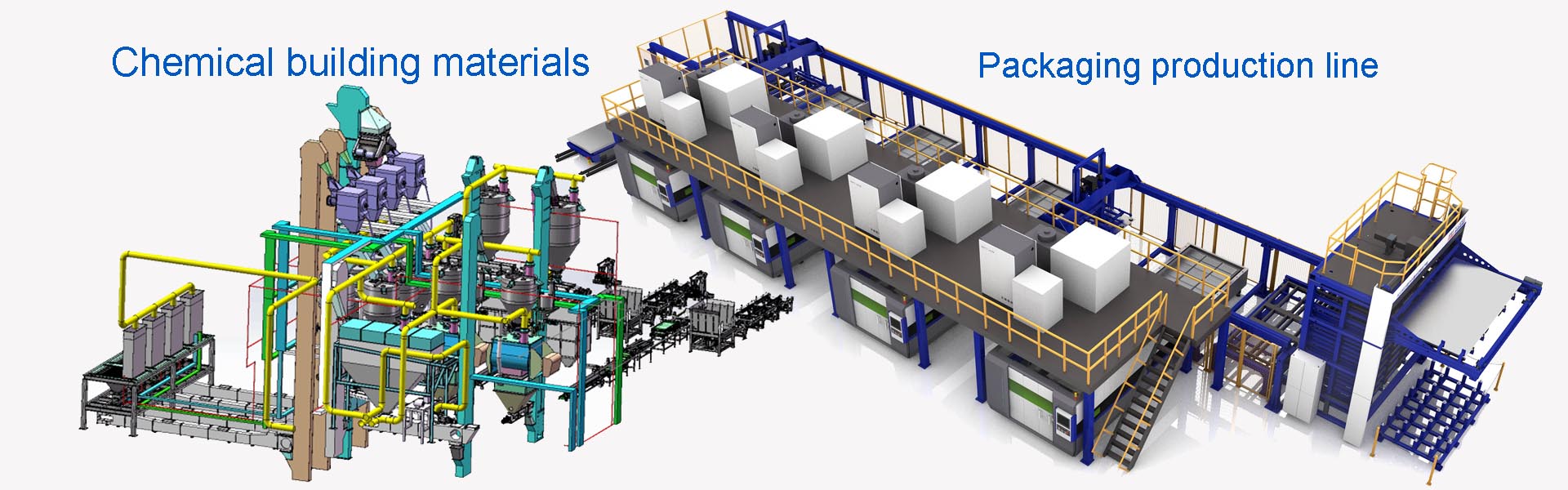

Chemical Manufacturing:

Packaging acids, bases, solvents, and other chemicals into industrial containers.

Tobacco Industry:

Filling tobacco extracts, e-liquids, and other tobacco-related products.

Food & Beverage:

Packaging sauces, dressings, and other viscous foods.

Pharmaceuticals:

Filling liquid medications, syrups, and ointments in bottles or pouches.

Automotive Industry:

Packaging engine oils, lubricants, and coolants for OEMs and aftermarket suppliers.

Cosmetic & Personal Care:

Filling lotions, creams, and other viscous cosmetic products.

Agriculture:

Packaging pesticides, fertilizers, and other agrochemicals.

Bulk Storage & Distribution:

Filling barrels, drums, or IBC totes for bulk storage and transportation.

Why Choose This Machine?

High Efficiency:

Fully automated operation reduces labor costs and increases production throughput.

Precision & Consistency:

Accurate filling volumes ensure product consistency and reduce waste.

Safety:

Designed with operator safety and product integrity in mind.

Scalability:

Can handle small batches or large-scale production runs.

Durability:

Robust construction ensures long-lasting performance in demanding environments.

Flexibility:

Adaptable to a wide range of container sizes and product viscosities.

Low Maintenance:

Easy to clean and maintain, reducing downtime and operational costs.

Environmental Compliance:

Minimizes spills and emissions, ensuring compliance with environmental regulations.

Conclusion:

The Piston Fully Automatic Honey Liquid Filling Machine is a versatile, high-precision solution for filling a wide range of liquids into various containers. Its advanced features, safety protocols, and versatility make it ideal for industries such as food, beverages, chemicals, pharmaceuticals, and automotive. Whether you’re producing honey, engine oil, or specialty chemicals, this machine delivers reliable performance, efficiency, and precision for your filling needs.

Immediate Order:

Website: http://www.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Fully Automatic Liquid Weighing Filling Machine for 220L[2025-05-09]

-

Fully Automatic Corrosive Liquid Barrel Filling Machine for 30L[2025-04-29]

-

Single-Head Semi-Auto Capping Filling Machine for 1-25L[2025-05-10]

-

Semi-Automatic Desktop Filling Machine for Filling 30L Resin Solvent/Lubricant[2025-04-01]