Quantitative Packaging Line, 18kg Grease Packaging Line Gravity Filling Machine

Quantitative Packaging Line with Gravity Filling Machine for 18kg Grease

Overview

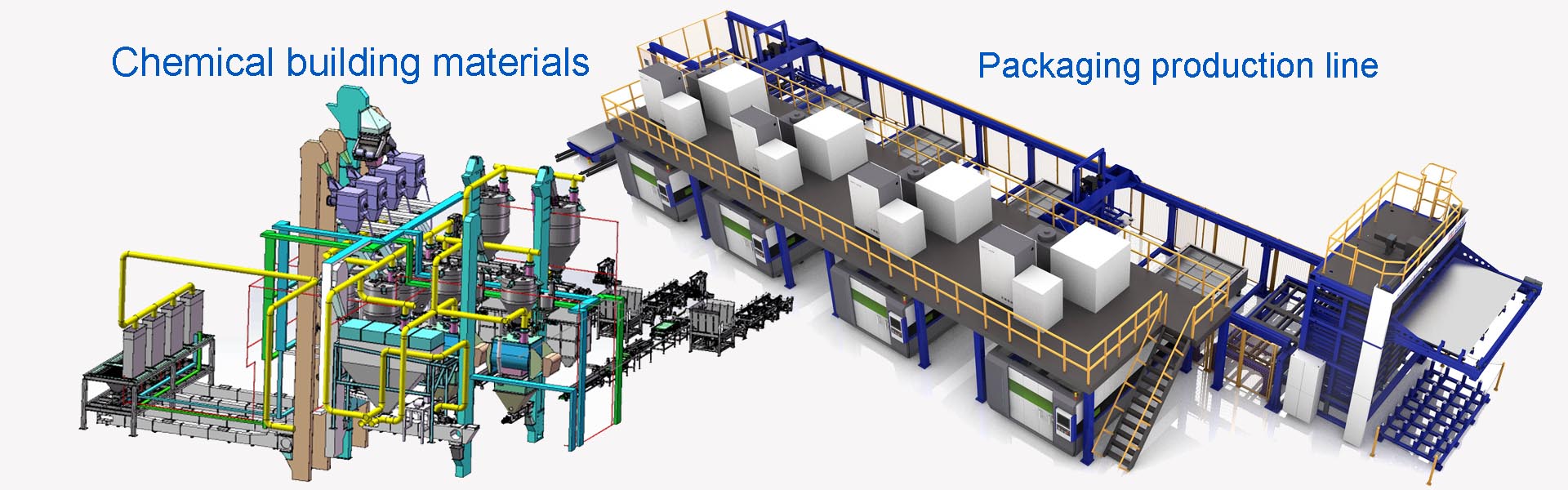

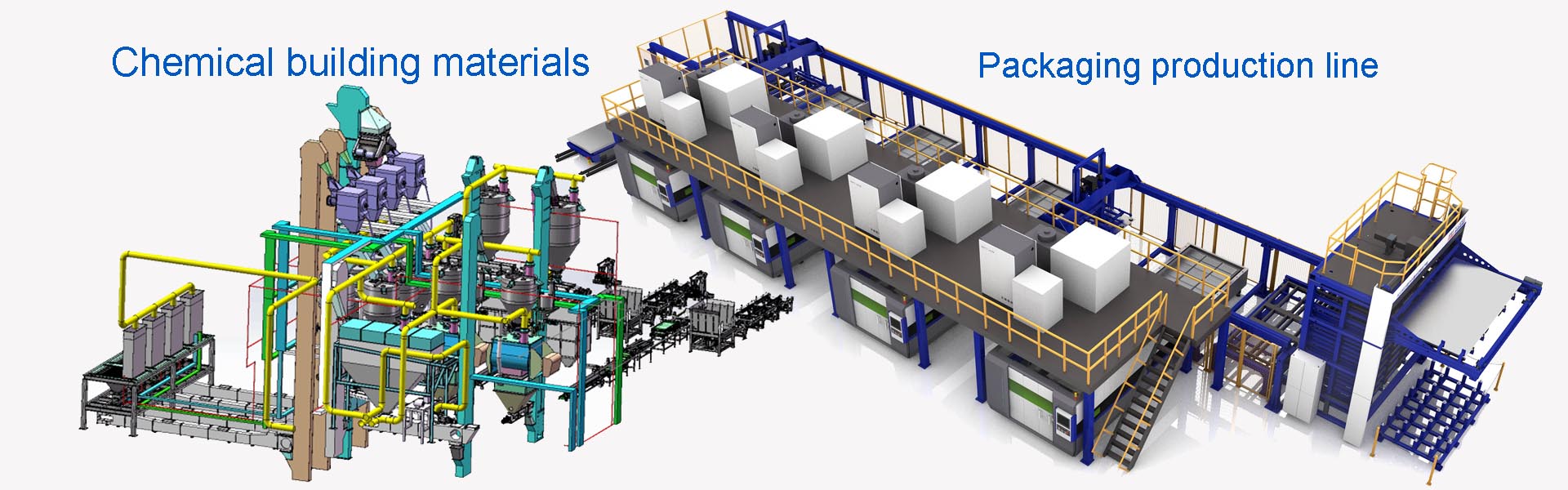

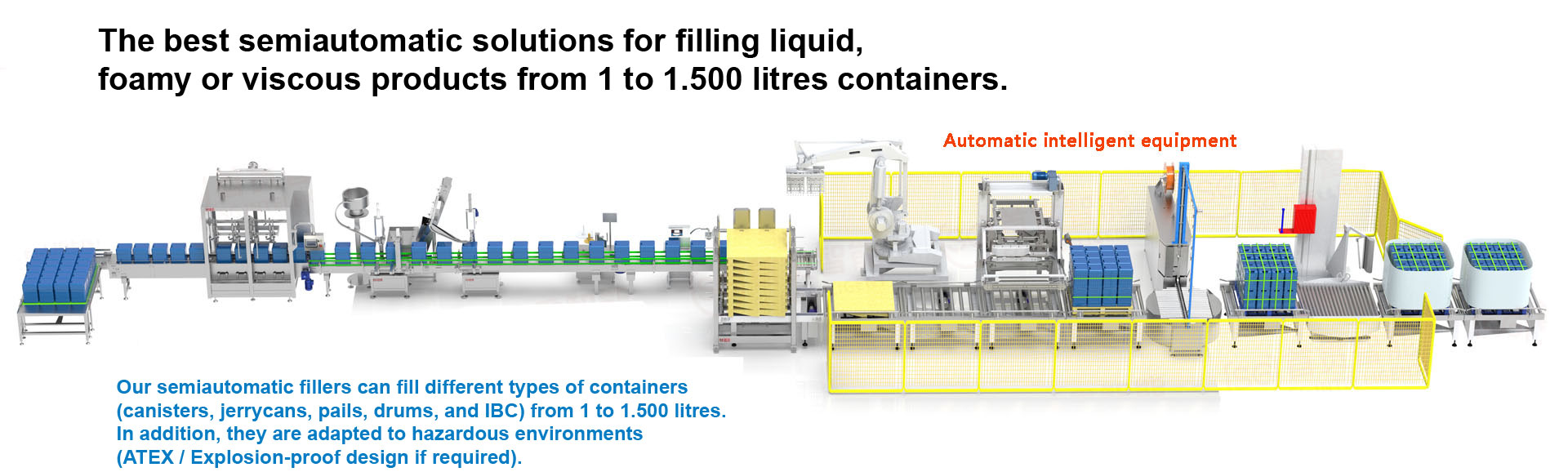

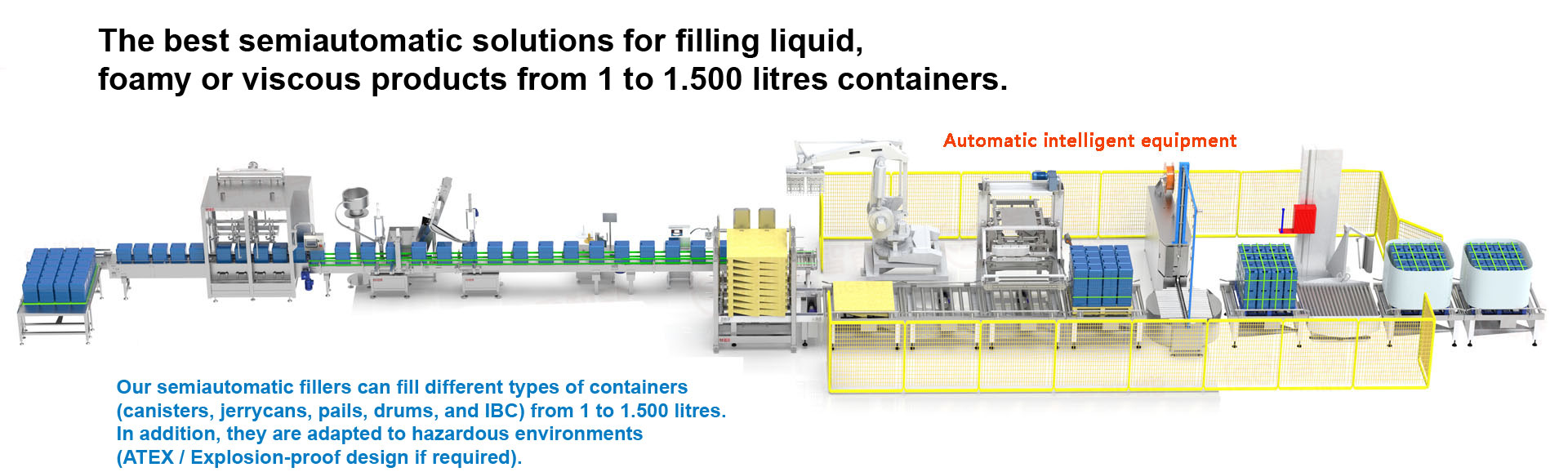

The 18kg Grease Quantitative Packaging Line is a high-capacity, gravity-fed filling system designed for precise and efficient packaging of grease, lubricants, or viscous liquids. It combines gravity filling technology with automated conveyors, weighing systems, and sealing modules to ensure accurate, consistent, and contamination-free packaging.

Key Features

Gravity Filling Technology

Precision Control: Accurate filling via gravity flow, ideal for viscous products like grease (18–20kg per container).

Drip-Free Nozzles: Stainless steel or ceramic nozzles prevent dripping or leakage during filling.

Adjustable Flow Rate: Customizable speed to handle varying product viscosities and minimize foaming.

Quantitative Accuracy

Weighing System: Integrated load cells with ±0.1% accuracy for consistent fill weights.

Automated Calibration: Real-time weight monitoring and adjustment to maintain target weight.

Overfill Prevention: Programmable fill cutoff to avoid excess product.

High-Capacity Handling

Container Compatibility: Suitable for pails, drums, or IBC totes (customized for 18kg containers).

Throughput: Up to 30 containers/hour (depends on container size and product viscosity).

Batch Processing: Supports large-scale production runs with minimal downtime.

Automation & Integration

Conveyor System: Automatic infeed/outfeed conveyor for seamless container handling.

Sealing Module (Optional): Integrated lid sealing or crimping for tamper-proof closures.

HMI Touchscreen: Easy recipe setup, real-time monitoring, and diagnostics.

Sanitation & Maintenance

Stainless Steel Construction: 304/316L stainless steel hopper, pipes, and frames for durability and hygiene.

CIP Cleaning System: Automatic cleaning-in-place for easy maintenance and contamination control.

Quick-Change Nozzles: Tool-free nozzle replacement for different container sizes.

Customization Options

Nitrogen Blanketing: Inert gas purge to prevent oxidation or contamination.

Barcode Printing/Scanning: Track batches, expiration dates, and ensure traceability.

Remote Monitoring: IoT-enabled connectivity for remote access and troubleshooting.

Technical Specifications

Filling Range: 1–20kg (adjustable in 0.1kg increments).

Accuracy: ±0.1% of target weight.

Materials: 304/316L stainless steel, PTFE/FKM seals.

Safety Rating: IP65 (dust and water resistant).

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Environment Compatibility: ATEX/IECEx compliant for hazardous areas (optional).

Operation Steps

Container Placement: Position the container under the filling nozzle via conveyor.

Start Cycle: Initiate filling via HMI touchscreen or automated sensors.

Gravity Filling: Product flows by gravity into the container, monitored by load cells.

Cutoff & Sealing: Filling stops automatically at target weight; optional sealing module secures the lid.

Conveyor Removal: Filled container is transported to downstream processes (e.g., labeling, capping).

Cleanup: Nozzles and hoses are purged with solvent or air (CIP system available).

Applications

Grease & Lubricants: Automotive grease, industrial lubricants, and heavy oils.

Food Industry: Dairy products, sauces, and viscous food additives.

Chemicals: Adhesives, coatings, and high-viscosity fluids.

Pharmaceuticals: Ointments, creams, and topical gels.

Industrial Products: Molten sulfur, waxes, and resins.

Benefits

Precision & Consistency: ±0.1% accuracy ensures uniform fill weights and reduced waste.

Efficiency: High throughput and automated workflows minimize labor costs and downtime.

Versatility: Customizable for different container sizes, product viscosities, and sealing requirements.

Low Maintenance: Robust construction and CIP compatibility reduce cleaning time and effort.

Safety: Drip-free nozzles and spill prevention protect operators and equipment.

Scalability: Easily expandable for larger production lines or integration with additional processes.

Why Choose Us?

As a manufacturer, we specialize in high-capacity, quantitative packaging solutions for viscous and semi-solid products. Our gravity filling machines are designed for accuracy, reliability, and ease of use, ensuring your production line meets the highest standards. Contact us for a tailored quote or consultation!

Immediate Order:

Website: http://www.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

Automatic Mouth-Finding Filling Machine Is Suitable for Ink Solvent/Polyurethane Filling[2025-05-07]

-

GZM-25 Weighing Filling Machine, a Filling Head with a Cap, Explosion-proof, Suitable for Chemical, Agriculture, Paint, Coating,[2025-04-28]

-

Small Bottle Syrup Oral Liquid Filling Machine Production Line[2025-06-06]

-

Automatic Gland Weighing Filling Machine for 50-30L Glacial Acetic Acid Filling[2025-04-07]