Environmentally Friendly High Efficiency Filling Machine for Curing Agent in Pail With Capping_

Environmentally Friendly High-Efficiency 25L Pail Filling Machine for Curing Agent with Automated Capping

Overview:

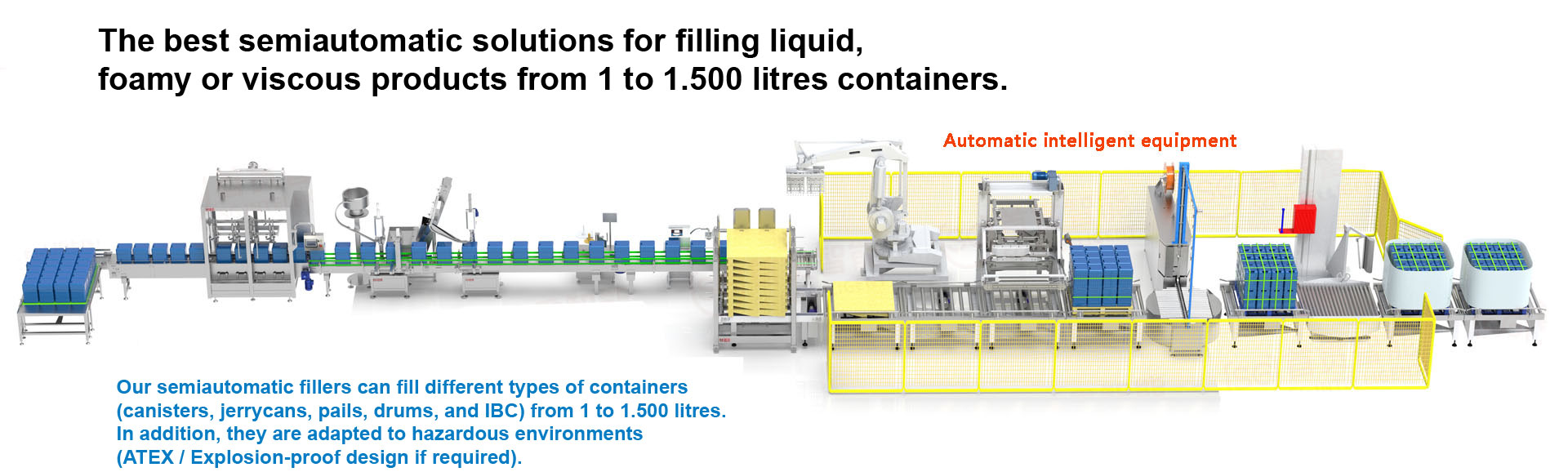

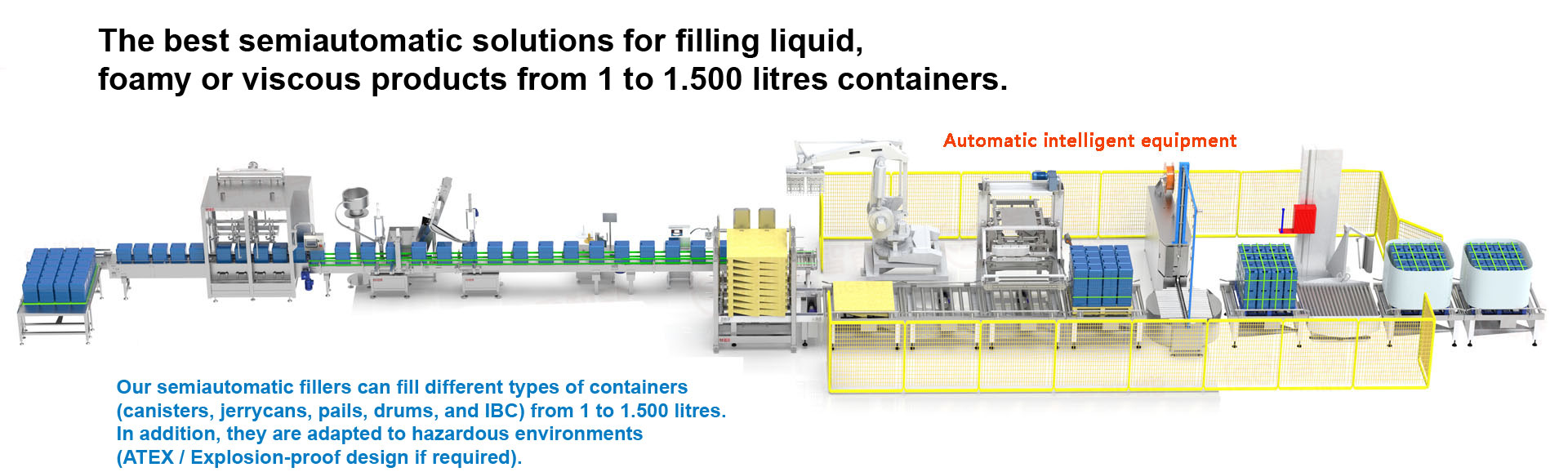

The High-Efficiency Filling Machine is designed for safe, precise, and eco-friendly filling of curing agents into 25-liter pails, complete with automated capping. It combines ATEX/IECEx explosion-proof safety, weight-based accuracy, and sustainable operation to ensure optimal performance in hazardous environments.

Key Features:

Safety & Compliance:

Ex-Proof Design: ATEX/IECEx certified for Zone 1/21 hazardous areas (flammable liquids).

Spark-Free Operation: Pneumatic components, static-dissipative materials, and explosion-proof electrical systems.

Corrosion-Resistant Materials: 316L stainless steel frame, PTFE-lined nozzles, and FKM/EPDM seals for chemical compatibility.

High Efficiency & Precision:

Weight-Based Filling: ±0.1% accuracy using load cells and real-time HMI monitoring.

Viscosity Handling: Pneumatic diaphragm pumps for medium viscosity (up to 5,000 cP) or optional gear pumps for higher viscosity.

Adjustable Parameters: Save recipes via HMI touchscreen for different products and pail sizes.

Automated Capping System:

Integrated Capping: Automatic screw capping or press-on lid closure with torque control.

Cap Dispenser: Optional automatic cap feeder for seamless operation.

Environmental Sustainability:

Spill Prevention: Drip trays, automatic nozzle purging, and spill-proof filling heads.

Low Emissions: Solvent recovery options (e.g., fume extraction or closed-loop systems).

Energy Efficiency: Low-power pneumatic operation and LED lighting.

User-Friendly Design:

HMI Touchscreen: Intuitive interface for recipe management, diagnostics, and training.

Quick-Change Nozzles: Tool-free swapping for cleaning or pail size adjustments.

Ergonomic Workflow: Manual pail loading with optional conveyor belt for increased throughput.

Customization Options:

Heating Systems: Jacketed nozzles or heated hoses for temperature-sensitive curing agents.

Fumes Management: Integration with fume extraction arms or solvent recovery systems.

Cleaning Accessibility: Removable drip trays and CIP (Clean-in-Place) options.

Technical Specifications:

Filling Range: 1–25 liters (adjustable for custom volumes).

Accuracy: ±0.1% of target weight.

Viscosity Handling: Up to 5,000 cP (higher with optional gear pumps).

Materials: 316L stainless steel, PTFE liners, FKM/EPDM seals.

Safety Certification: ATEX, IECEx, and CE compliant.

Environment Rating: IP65 (dust and water resistant).

Power Requirements: 220V/50Hz or 110V/60Hz (customizable).

Applications:

Curing Agents: Epoxy, polyurethane, and other industrial curing agents.

Chemical Resins: Epoxy, polyester, and other industrial resins.

Paints & Coatings: Solvent-based, water-based, or high-viscosity paints.

Operation Steps:

Container Placement: Manually place the 25L pail under the filling head.

Start Filling: Initiate the cycle via foot pedal or HMI touchscreen.

Weight-Based Filling: The machine fills the pail to the preset weight, stopping automatically.

Automated Capping: The integrated capping system applies and tightens the lid (if equipped).

Container Removal: Remove the filled and capped pail manually or via conveyor (optional).

Cleanup: Nozzle self-purges or undergoes manual cleaning to prevent cross-contamination.

Benefits:

Safety in Hazardous Areas: Ex-proof design ensures compliance with ATEX/IECEx standards for flammable environments.

Precision & Consistency: Weight-based filling minimizes waste and ensures accurate batches.

Eco-Friendly Operation: Spill prevention, solvent recovery, and energy-efficient design reduce environmental impact.

Versatility: Handles a wide range of viscosities and pail sizes with adjustable parameters.

Low Maintenance: Robust construction, quick-clean components, and CIP options minimize downtime.

Customization: Tailored capping, heating, and fumes management options for specific applications.

Why Choose Us?

As a manufacturer, we specialize in hazardous environment filling solutions for curing agents, chemical resins, and other flammable liquids. Our machines are built to balance safety, precision, and sustainability while offering flexibility for your unique needs. Contact us for a tailored quote or consultation!

Immediate Order:

Website: http://www.xtsy120.com/product/drumfillingmachines-en.html

China Manufacturing Co Ltd.: https://fillingmachinecn.en.made-in-china.com

-

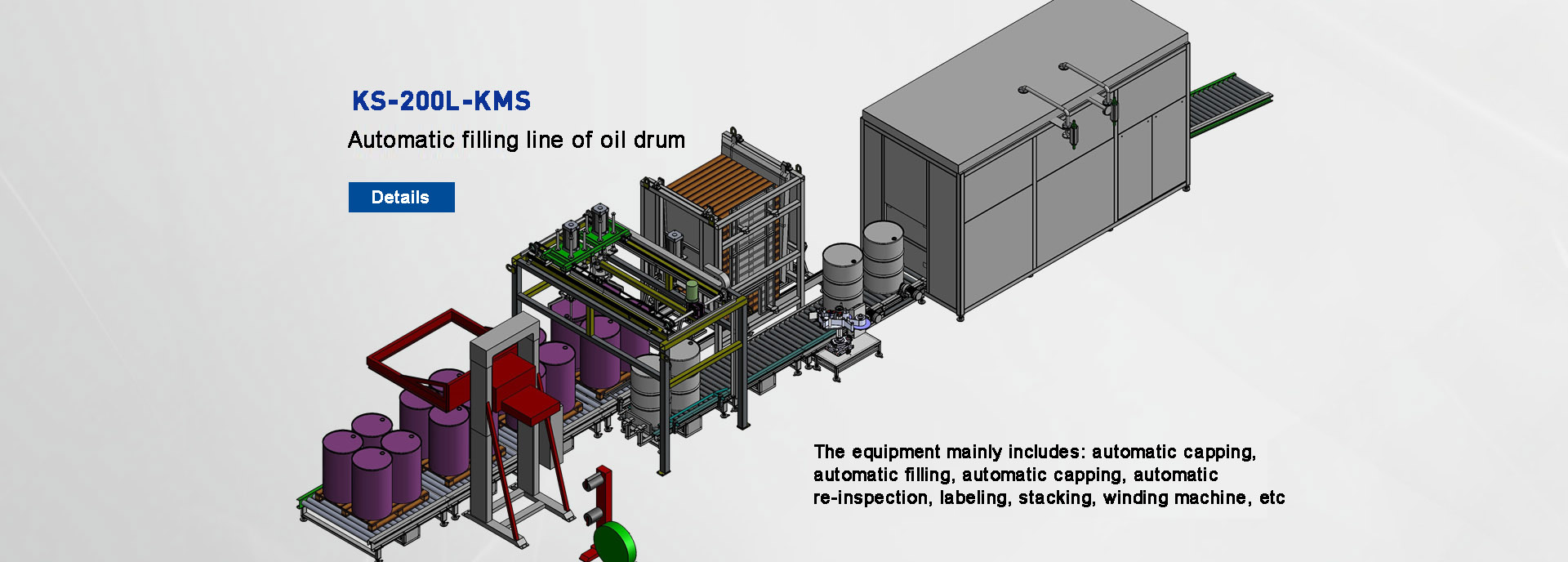

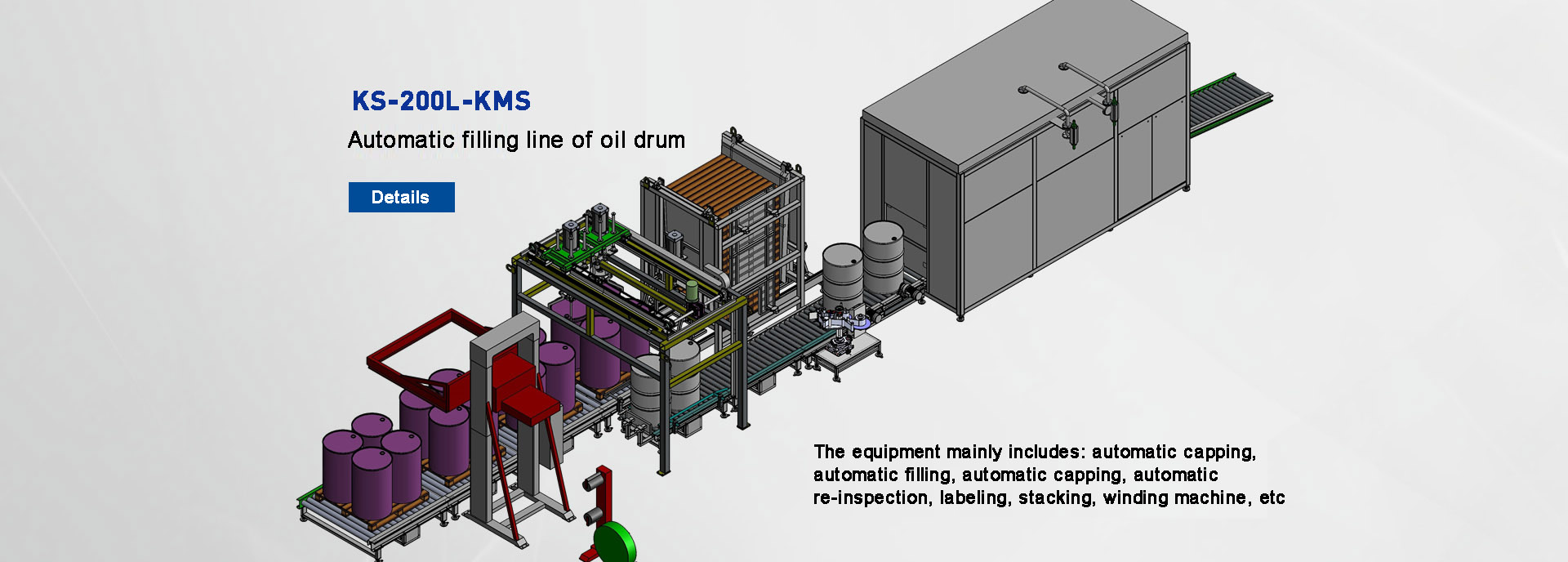

200L Fully Automatic High Temperature Bitumen/Asphalt Filling Machine[2025-04-15]

-

Semi Auto Powder Filler / Dry Powder Filling Machine[2025-04-12]

-

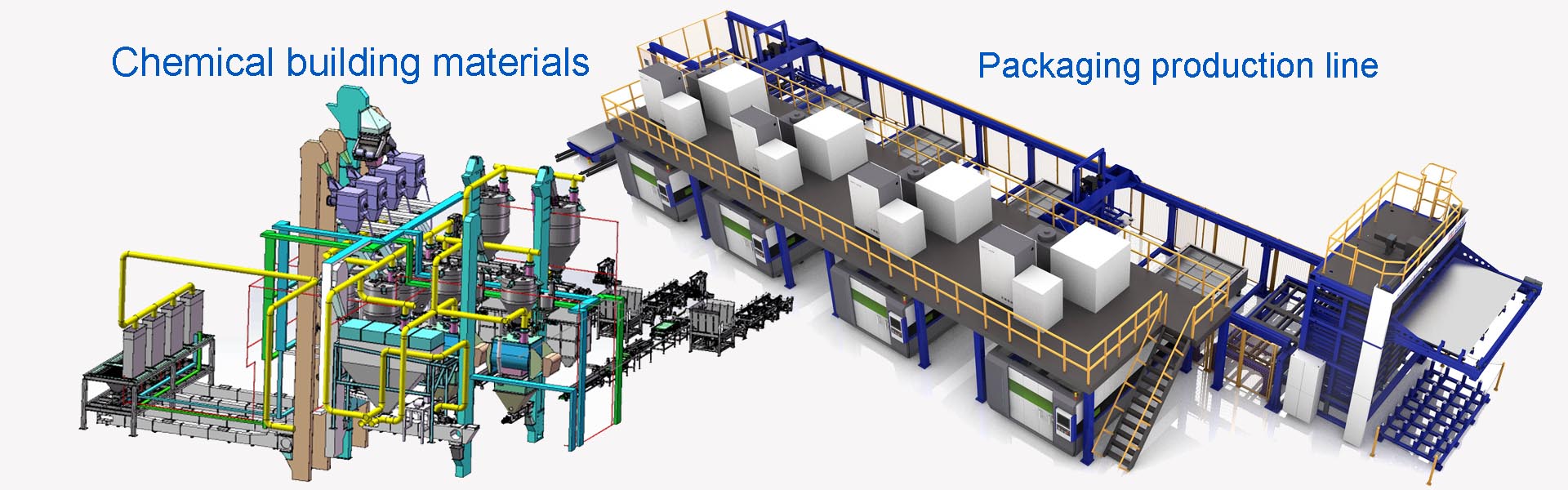

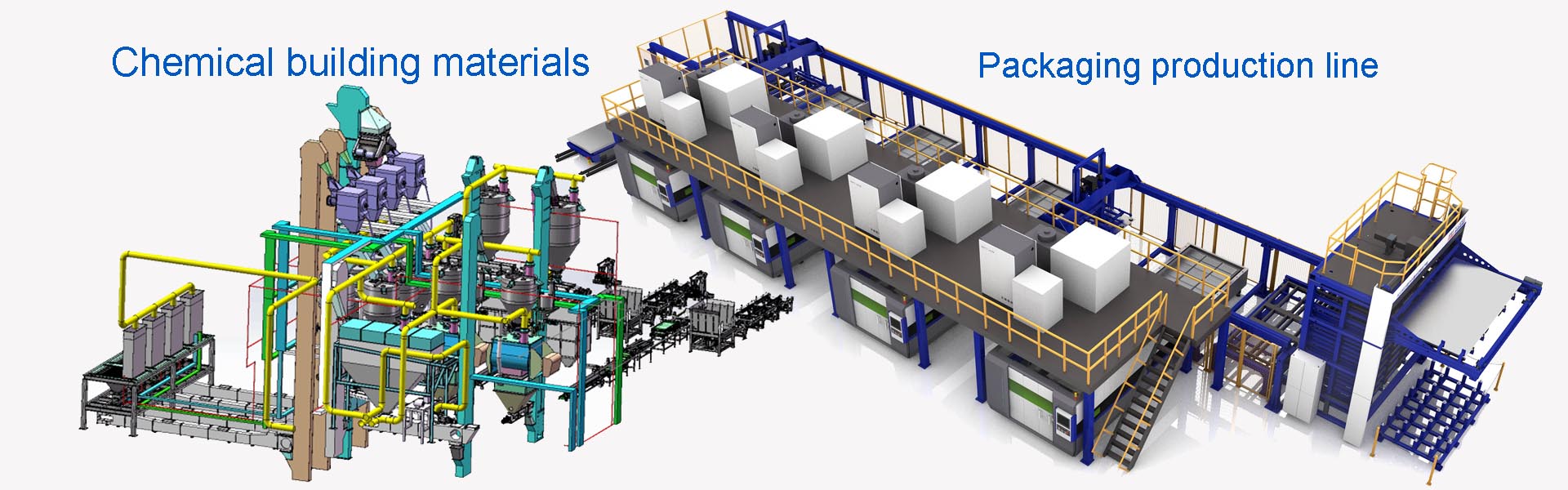

Fully Automatic Chemical Resin Pails Filling Machine with 30L Filling Line[2025-04-08]

-

Automatic 5 Gallon Bottle Mineral Water Filling Machine[2025-04-12]